KEY BENEFITS

Measure part features and complex profile geometries informed by real-time deviation display between CAD and measured data for real-time decisions. Produce one-click inspection reports in standard or custom, shareable formats that feed to your quality management system.

The Measure module’s device interface operates and optimizes most popular measurement systems making them more productive and ensuring a better return on your investment. You can also import externally captured data and process it against the nominal CAD model and tolerances. Even run datasets offline with feature extraction and pre-defined datums and constraints.

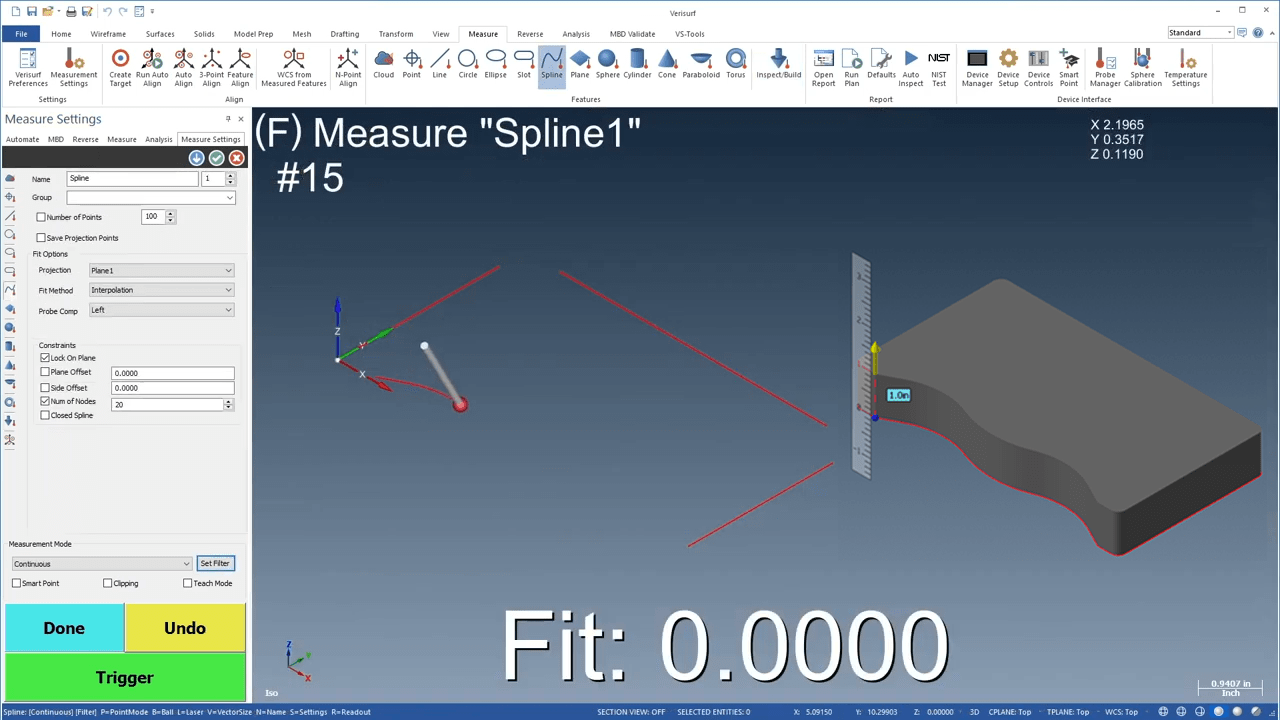

Measurement Flexibility

- Intuitive, workflow-based environment enables fast inspection from both 2D drawings and 3D models

- Rich, visual assist and feedback for real-time scrutiny of dimensions, profile, position, GD&T

- Both single point probing and high volume non-contact scanning of large cloud datasets

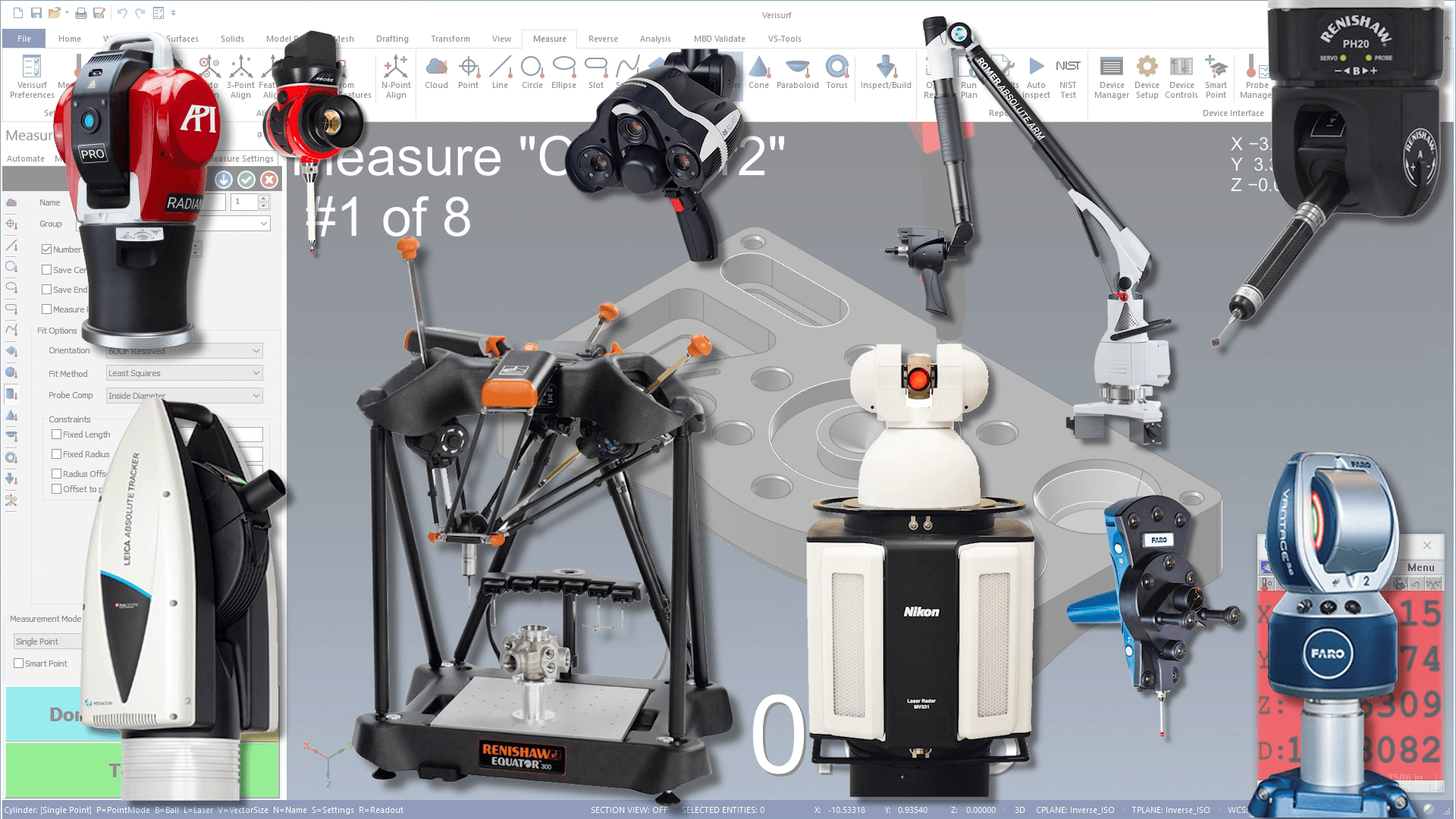

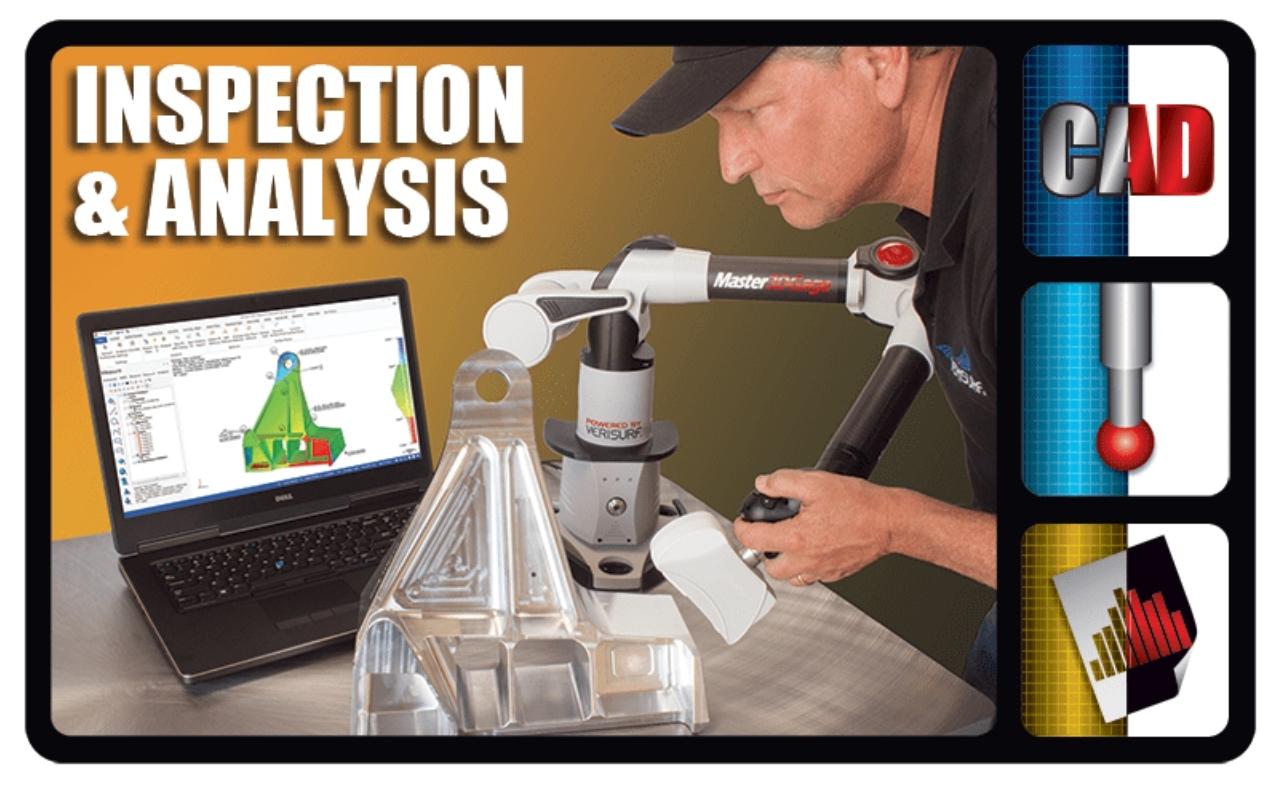

One Software for All Devices

- Operate and optimize multiple measuring devices simultaneously

- Measure with any brand or model portable probing and scanning system, manual and CNC CMMs, and digital gages

- Easily switch between single-point, continuous-point and point cloud scan modes

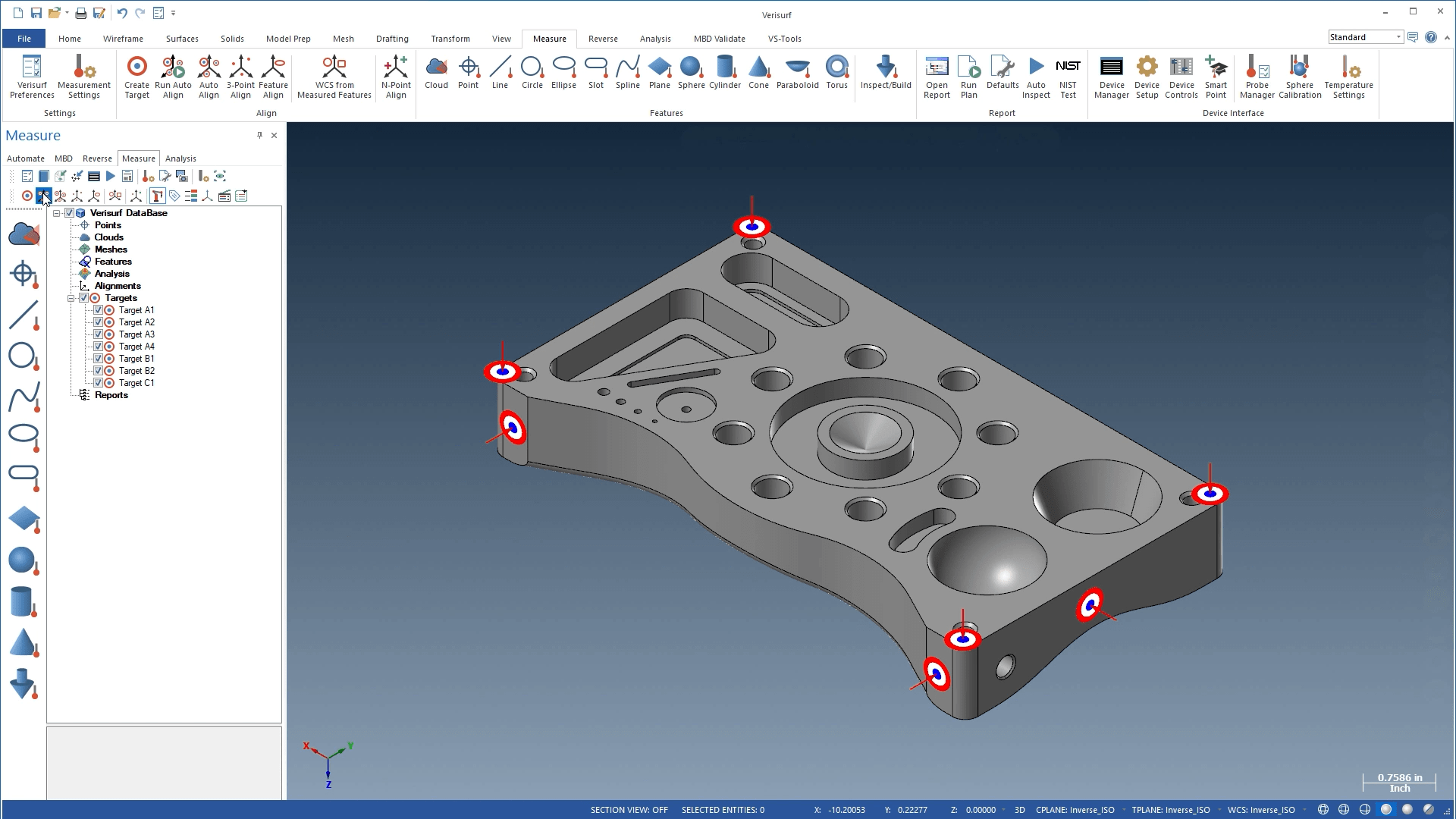

Fast Repeatable Alignments

- Auto Align makes aligning easy, works exceptionally well on complex shapes, and lends an extra level of process control to the inspection

- Feature Align makes it simple to align from measured features, guiding with visual cues that assist with the workflow

- Alignments are saved in the CAD file to ensure part-to-part repeatability and to automate the procedure

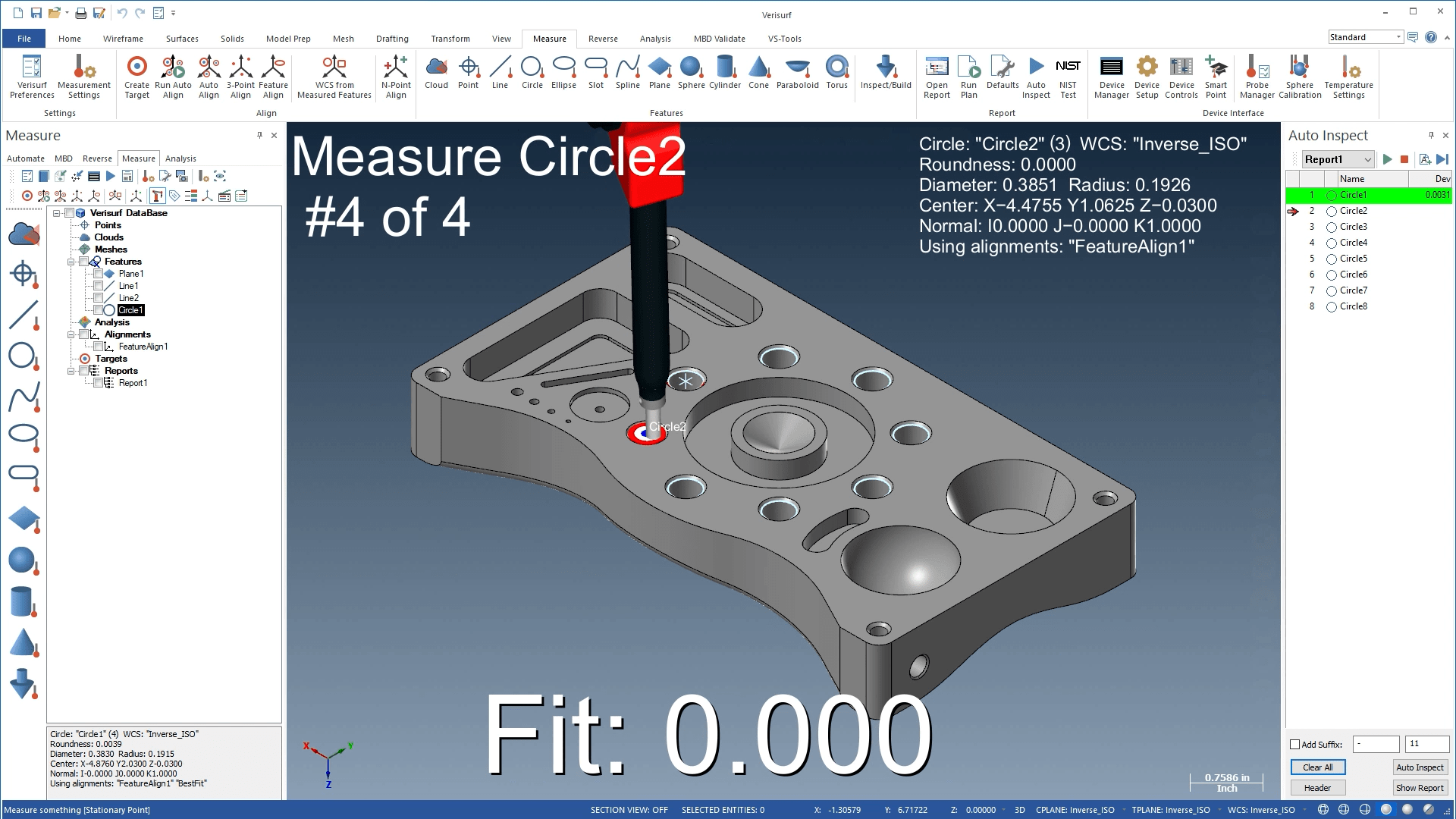

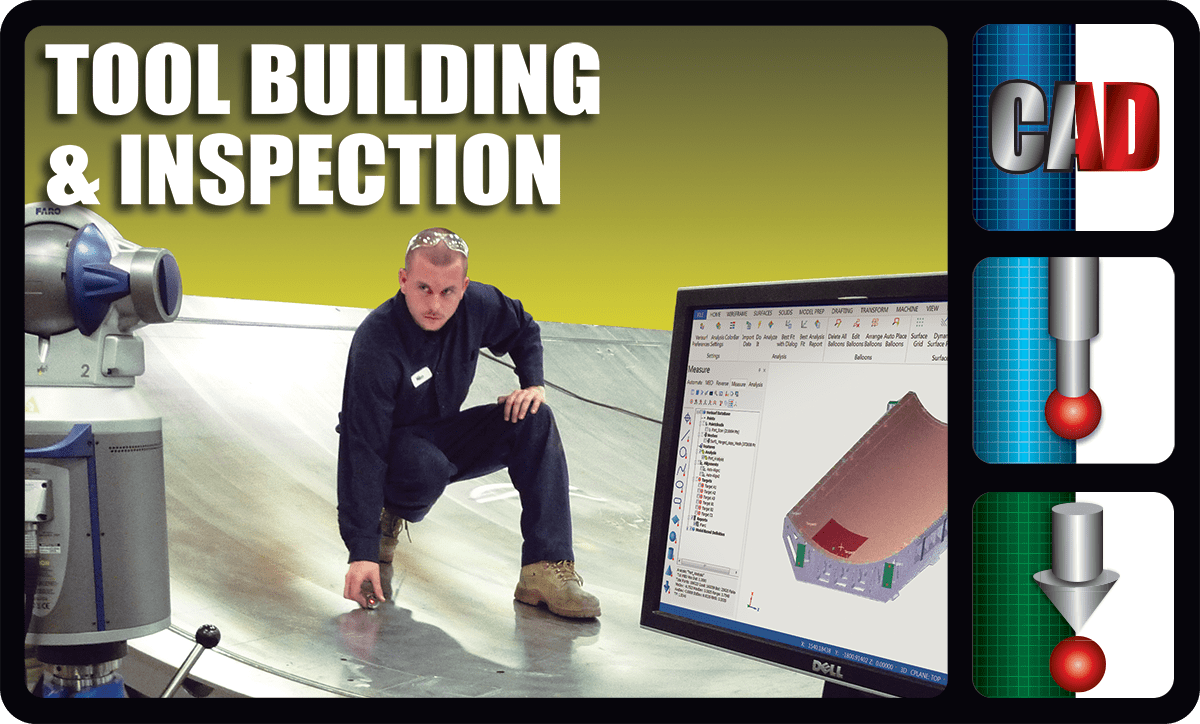

Automated Inspection Plans

- Inspection plans that can be used much like a playlist, that prompts the operator through the inspection

- Plans are created quickly and easily by picking features and measurement controls from the part model, or with “Teach Mode,” measure and playback

- Adds process control for manual measuring devices, and plans can be easily adapted for motorized/automated machines

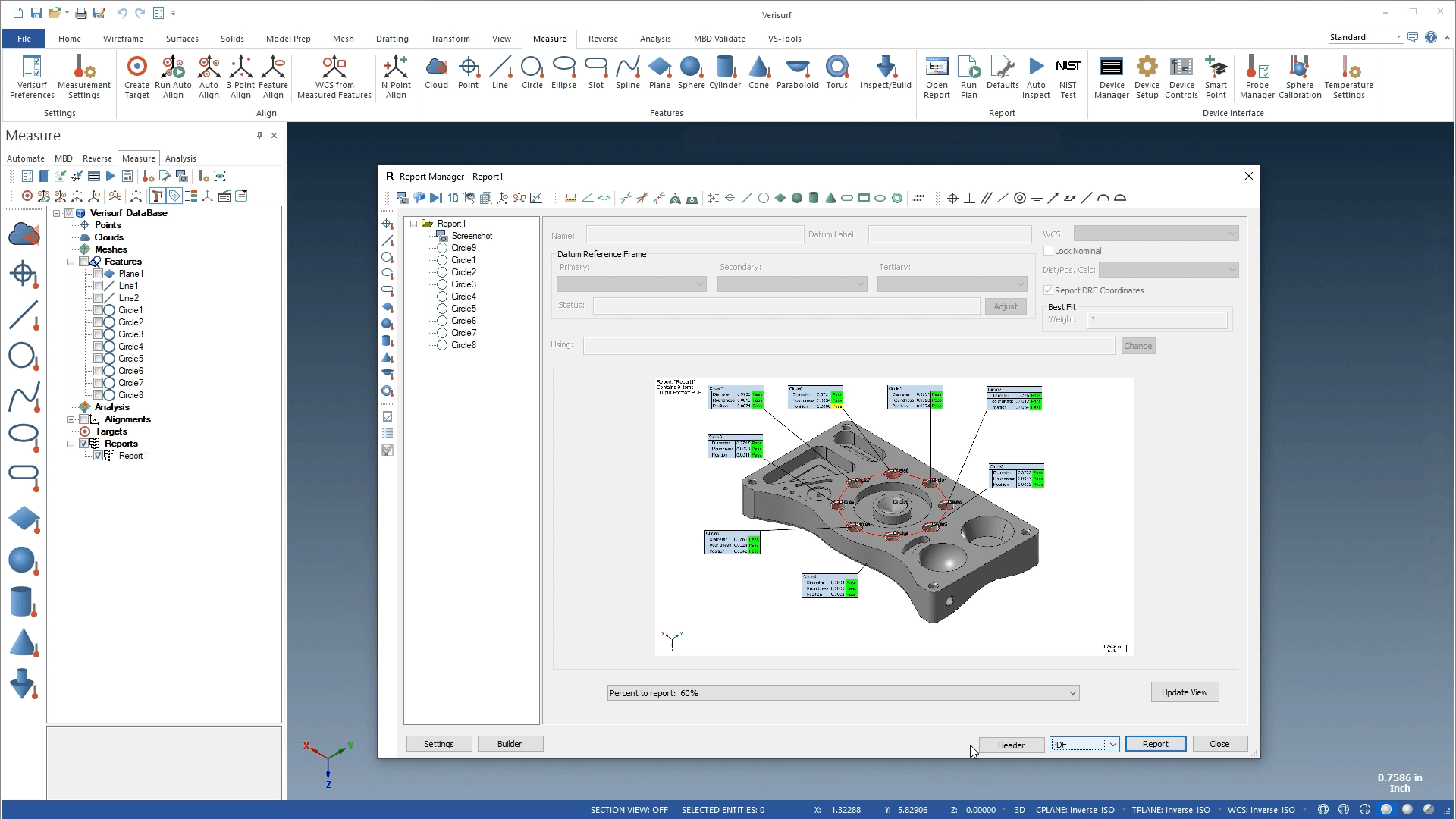

Quality Reporting

- First Article Inspection Reporting for AS9102 and PPAP ballooned drawing forms

- Intelligent GD&T, model-based tolerances applied to reports

- One-click reporting from standardized templates or custom forms for output to all common report formats

Probe-Based Reverse Engineering

- Measured features are automatically converted to CAD

- Features can be saved as-measured or dimensions can be tweaked to the perceived design intent

- Multi-edit saves time by allowing user to adjust several feature dimensions simultaneously

The Foundation of Real Time Measurement Suites.

Verisurf CAD and MEASURE modules are the online measurement foundation of Verisurf.

Once you have the basics of measurement you can add specialized modules for your specific Application Suite.