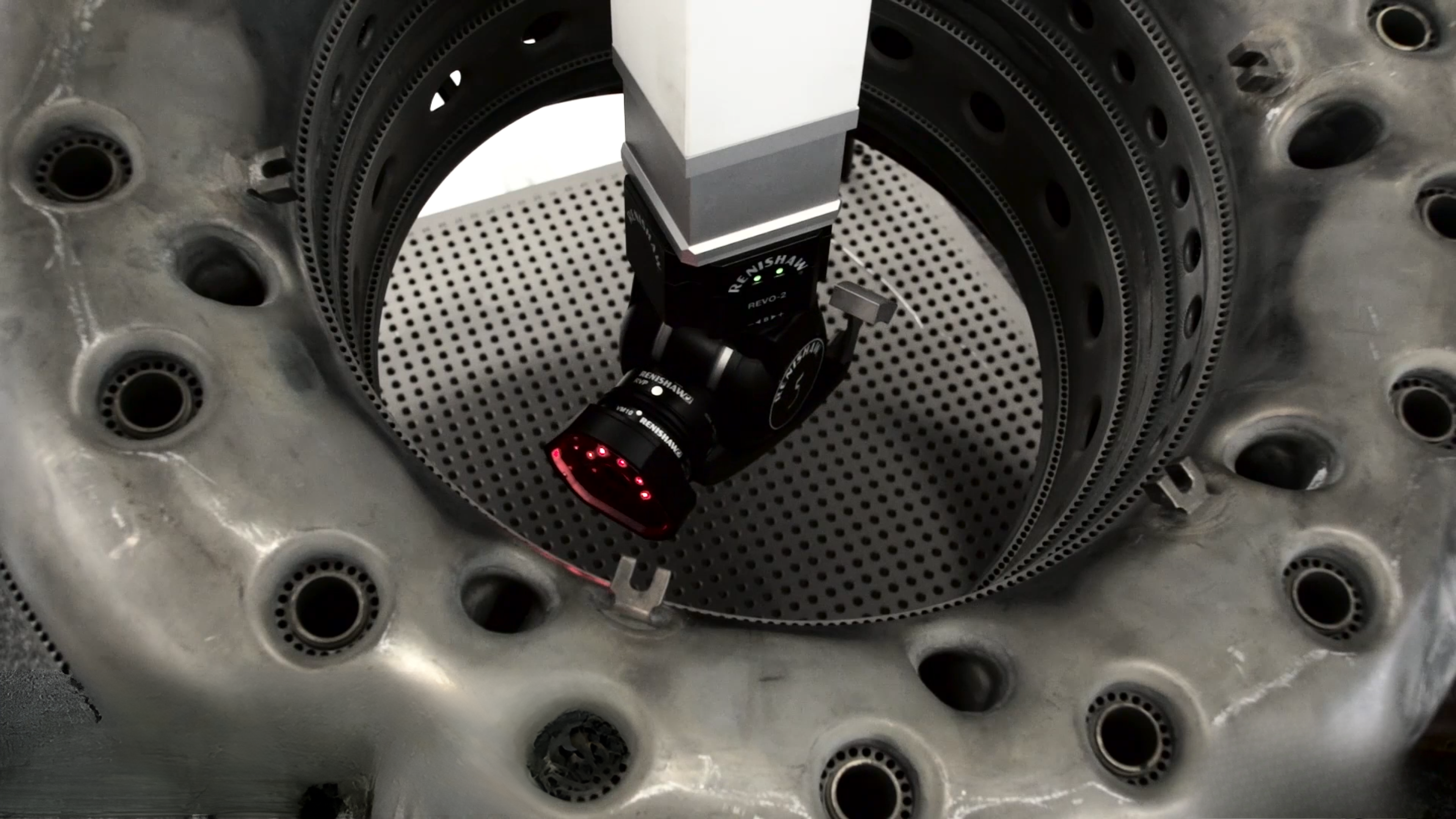

Verisurf CMM Programming Renishaw REVO Vision

Coordinate Measuring Machines (CMMs) are essential tools for ensuring quality in manufacturing. However, traditional CMM inspection can sometimes be limited when dealing with complex geometries or delicate parts. That’s where advanced probing solutions, such as the Renishaw REVO Vision, come in. When combined with powerful metrology software like Verisurf CMM Programming, the REVO Vision can significantly enhance CMM inspection capabilities, offering increased speed, accuracy, and versatility.

What is the Renishaw RVP?

The Renishaw RVP is a vision probe designed for use with Renishaw’s REVO 5-axis measurement system. It adds non-contact vision inspection to the REVO system, enabling CMMs to perform a wider range of inspection tasks.

Benefits of Combining Verisurf and Renishaw RVP:

- Expanded Inspection Capabilities: The RVP allows for the inspection of features that are difficult or impossible to measure with traditional touch probes. This includes small, delicate features, soft materials, and complex geometries. Verisurf software seamlessly integrates this capability, providing a unified platform for both contact and non-contact inspection.

- Increased Speed and Efficiency: The RVP’s non-contact measurement capability can be significantly faster than traditional probing, especially for parts with many small features. Verisurf software further enhances efficiency through streamlined programming, automated inspection routines, and rapid data processing.

- Improved Accuracy: Vision-based measurement can provide high accuracy, particularly for 2D features and edge detection. Verisurf’s advanced algorithms ensure precise data analysis and reporting, maximizing the accuracy of the RVP.

- Enhanced Automation: Verisurf software enables the automation of complex inspection routines involving both touch probing and vision measurement. This allows for unattended operation and increased productivity.

- Simplified Programming: Verisurf’s intuitive user interface simplifies the programming of RVP inspection routines. Users can easily define measurement paths, specify vision parameters, and generate inspection programs with minimal effort.

These benefits are realized through the powerful combination of Verisurf CMM Programming Renishaw REVO Vision. This integrated solution provides manufacturers with a comprehensive platform for both contact and non-contact inspection, streamlining workflows and ensuring accurate results.

Applications:

The combination of Verisurf and Renishaw RVP is ideal for a wide range of applications, including:

- Inspection of electronic components

- Measurement of delicate parts

- Quality control of plastic parts

- Reverse engineering of complex shapes

By integrating the Renishaw RVP with Verisurf metrology software, manufacturers can unlock a new level of CMM inspection capability. This powerful combination offers increased speed, accuracy, versatility, and automation, enabling users to tackle even the most challenging inspection tasks with confidence.