Verisurf CMM Programming Renishaw REVO RSP3 Scanning

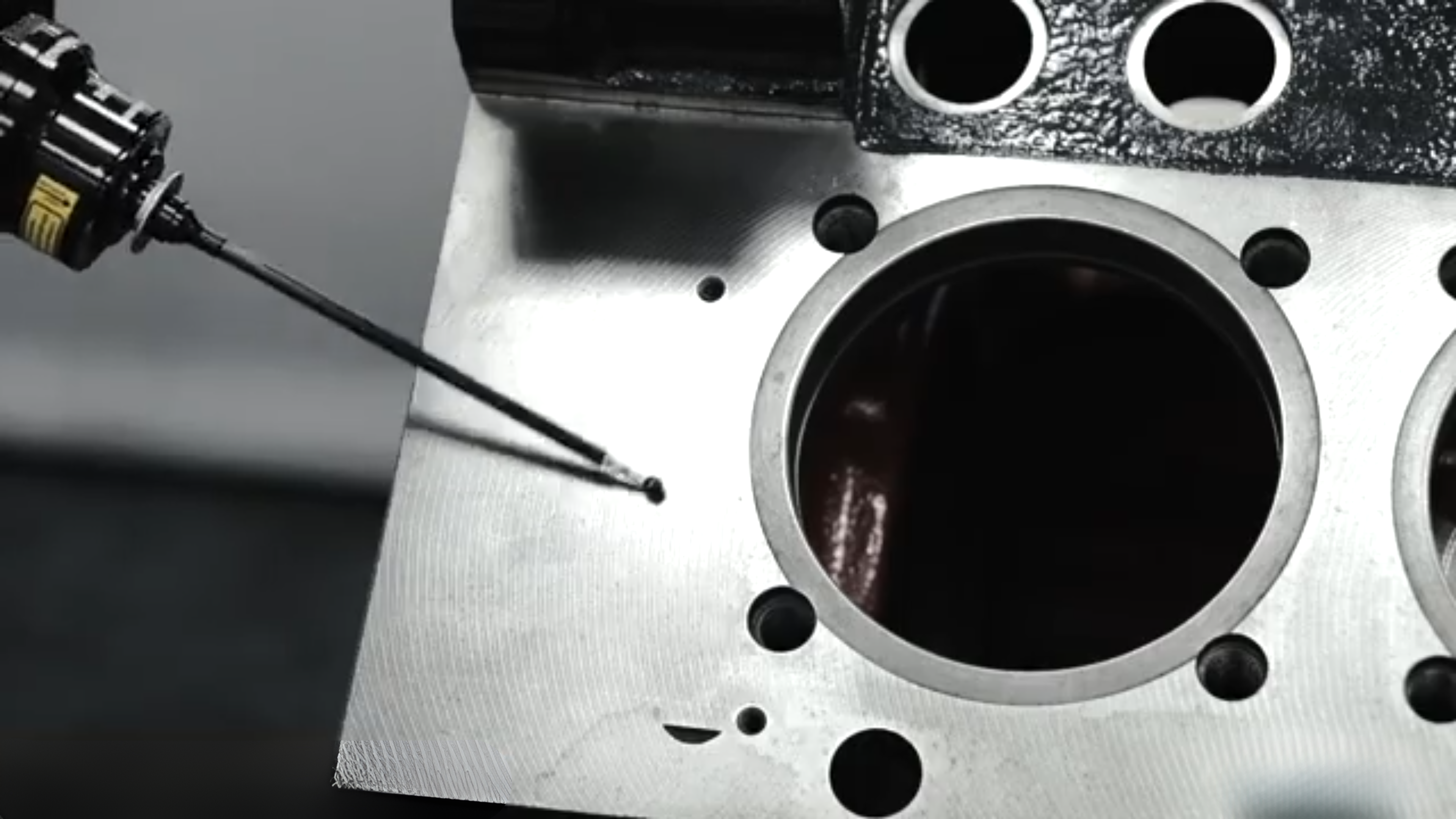

Coordinate Measuring Machines (CMMs) are indispensable tools for ensuring quality in manufacturing. To capture complex surface data effectively, advanced scanning probes are essential. The Renishaw REVO RSP3 is a key solution for high-performance 3D CMM scanning. When combined with Verisurf CMM Programming, it provides manufacturers with a powerful and comprehensive solution for demanding inspection applications.

What is the Renishaw REVO RSP3?

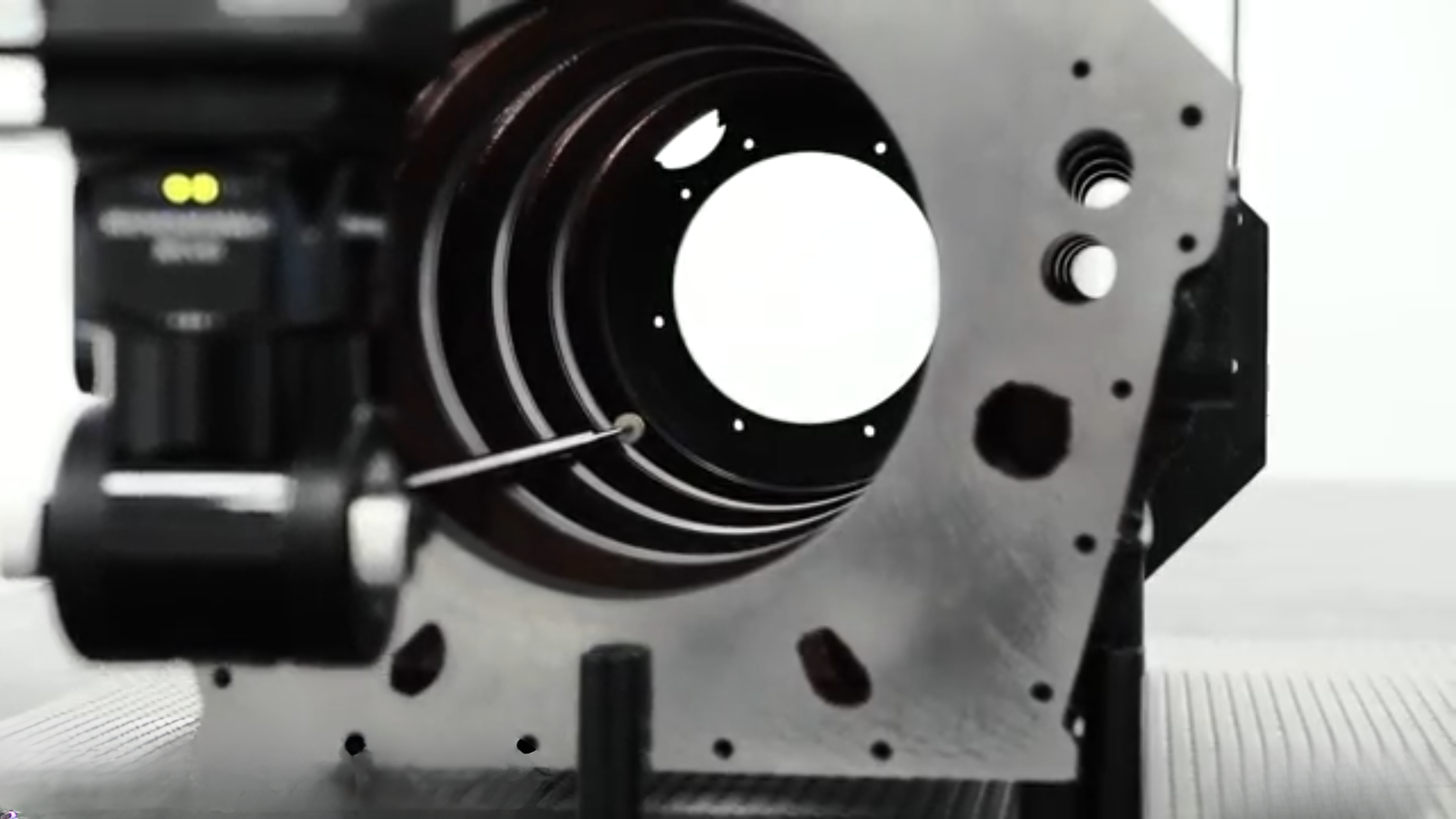

The Renishaw REVO RSP3 is a 3D scanning probe designed for Renishaw’s REVO 5-axis measurement system. The RSP3 range of 3D scanning probes complements the REVO-2 probe, providing the REVO system with 3D-scanning (x,y,z), crank stylus capabilities, and enhanced capability for carrying long styli. It enables CMMs to perform high-speed, high-accuracy tactile scanning in 3D, allowing for the efficient capture of dense point cloud data from intricate parts and complex geometries.

Benefits of Combining Verisurf CMM Programming and Renishaw REVO RSP3:

- Streamlined CMM Programming for Scanning: Verisurf CMM Programming provides a robust platform for programming, executing, and analyzing REVO RSP3 scanning routines. This optimized workflow, driven by Verisurf CMM Programming Renishaw REVO RSP3 Scanning capabilities, covers everything from scan path planning to data processing and reporting.

- Efficient 3D Data Management: Verisurf’s software effectively handles and manages the large volumes of 3D data acquired by the REVO RSP3, ensuring efficient processing, analysis, and storage. The efficiency of this process is a direct result of the design of Verisurf CMM Programming to work seamlessly with the Renishaw REVO RSP3.

Advanced 3D Data Analysis in Verisurf: Verisurf offers a comprehensive suite of tools for analyzing the rich 3D point cloud data captured by the REVO RSP3. This includes advanced feature extraction, detailed deviation analysis, and accurate surface reconstruction, all enhanced by Verisurf CMM Programming. - Seamless CAD Integration with Verisurf CMM Programming: Verisurf’s model-based metrology approach enables seamless integration of REVO RSP3 scan data with CAD models, facilitating powerful comparisons, analysis, and reporting. This integration is a cornerstone of Verisurf CMM Programming’s value.

- Enhanced Automation Capabilities with Verisurf: Verisurf software empowers users to automate complex 3D inspection routines involving the REVO RSP3, leading to increased efficiency, improved productivity, and reduced operator errors. Automation is greatly enhanced through Verisurf CMM Programming of the Renishaw REVO RSP3.

Applications:

The combination of Verisurf CMM Programming and Renishaw REVO RSP3 is ideally suited for applications requiring precise 3D data capture and in-depth surface analysis, such as:

- Complex aerospace component inspection

- Automotive body and frame analysis

- Medical implant measurement

- Reverse engineering of intricate parts

In each of these applications, Verisurf CMM Programming Renishaw REVO RSP3 Scanning provides a powerful solution.

The Renishaw REVO RSP3 3D scanning probe is a valuable asset for advanced CMM metrology, and Verisurf CMM Programming significantly enhances its capabilities. By providing streamlined CMM programming, powerful 3D data analysis tools, and seamless CAD integration, Verisurf enables manufacturers to fully leverage the potential of the REVO RSP3 for high-performance 3D scanning and comprehensive inspection.

The future of CMM metrology relies on solutions like Verisurf CMM Programming Renishaw REVO RSP3 Scanning.