Verisurf CMM Programming Renishaw REVO RSP2 Scanning

In today’s manufacturing landscape, speed and precision are paramount. Coordinate Measuring Machines (CMMs) play a crucial role in quality control, and advanced scanning probes like the Renishaw REVO RSP2 are essential for capturing detailed measurement data. This article explores how Verisurf CMM Programming maximizes the high-speed scanning capabilities of the Renishaw REVO RSP2, enabling manufacturers to achieve faster and more accurate inspection results.

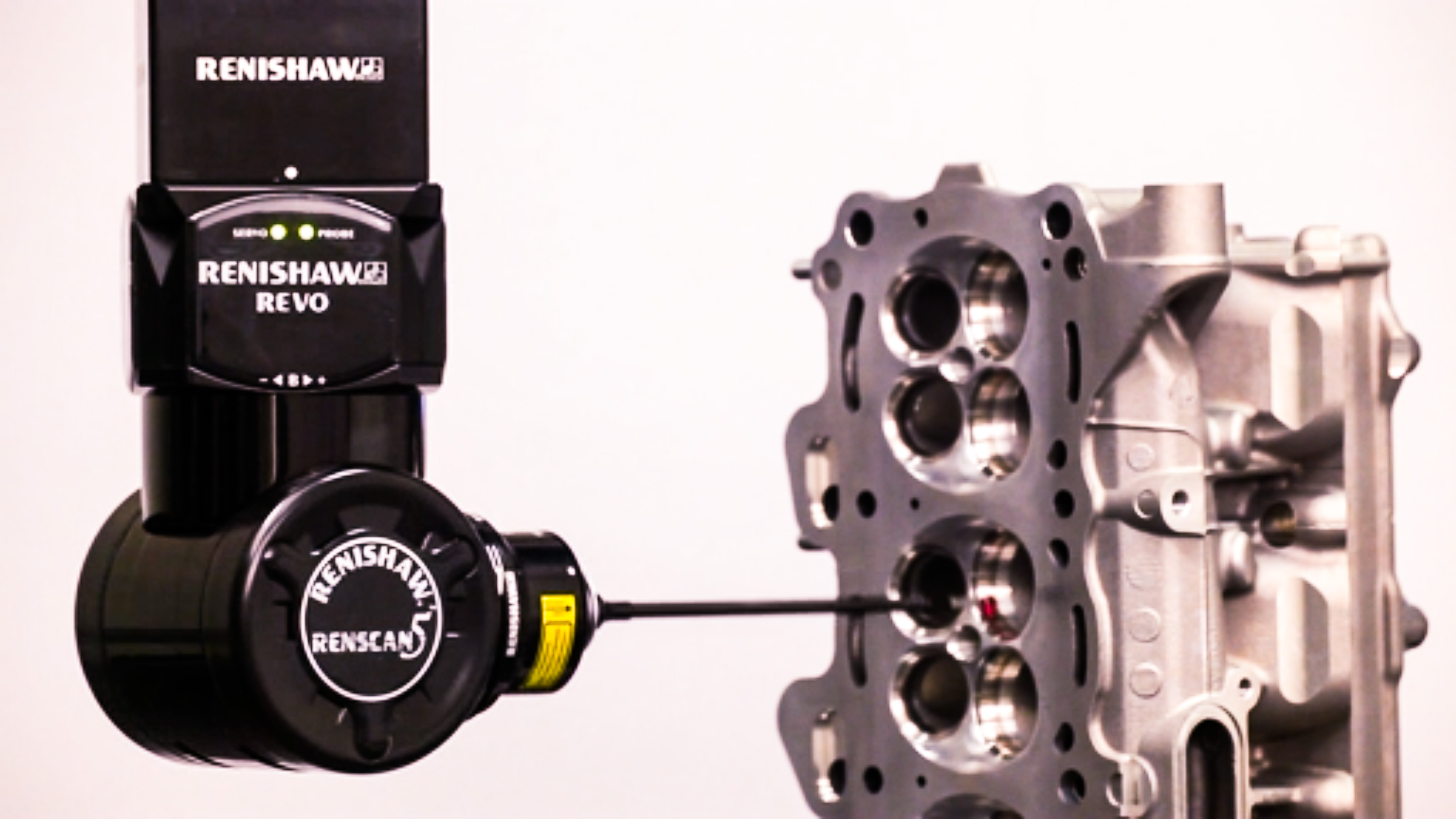

The Power of Renishaw REVO RSP2 for High-Speed Tactile Scanning:

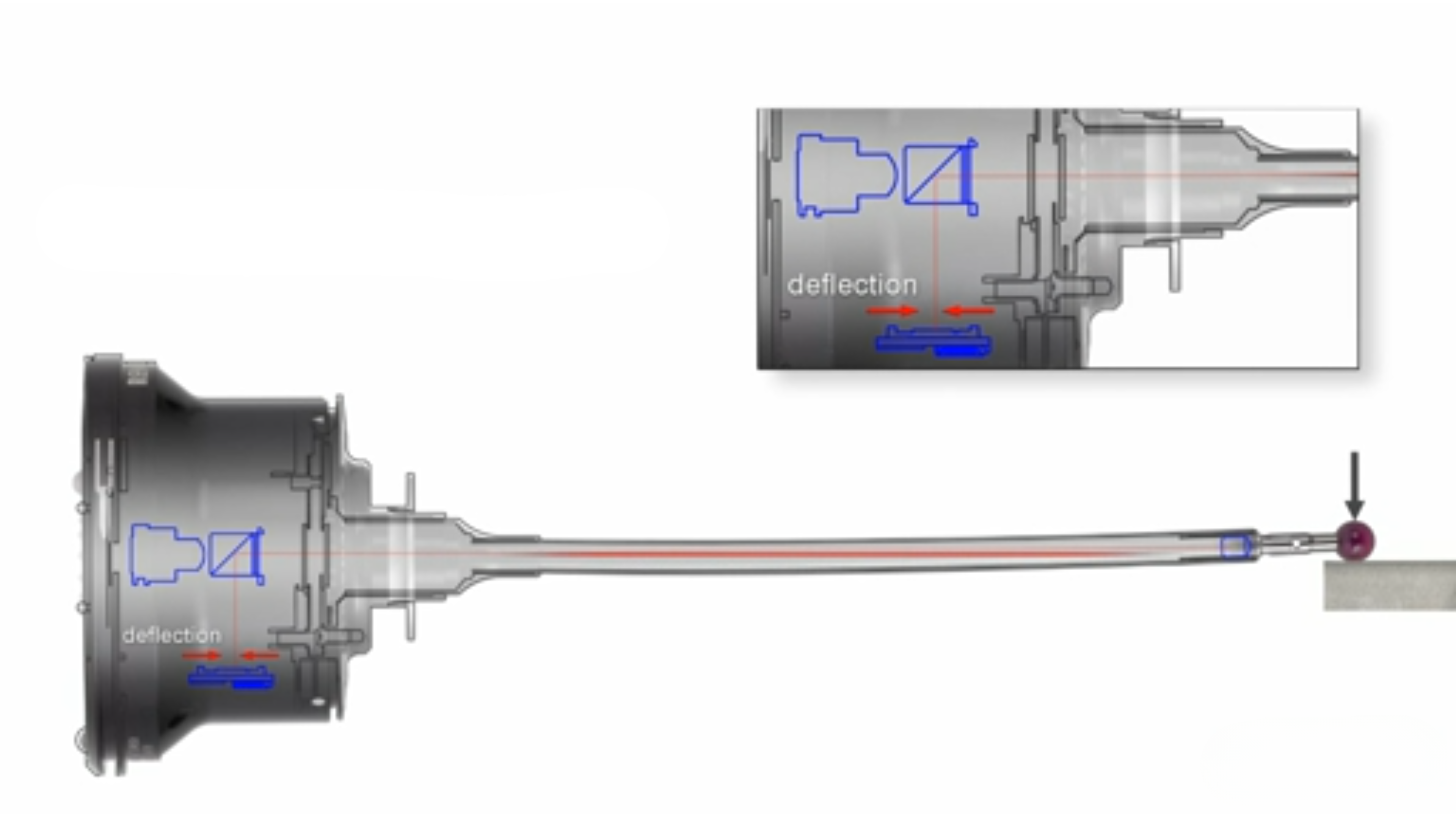

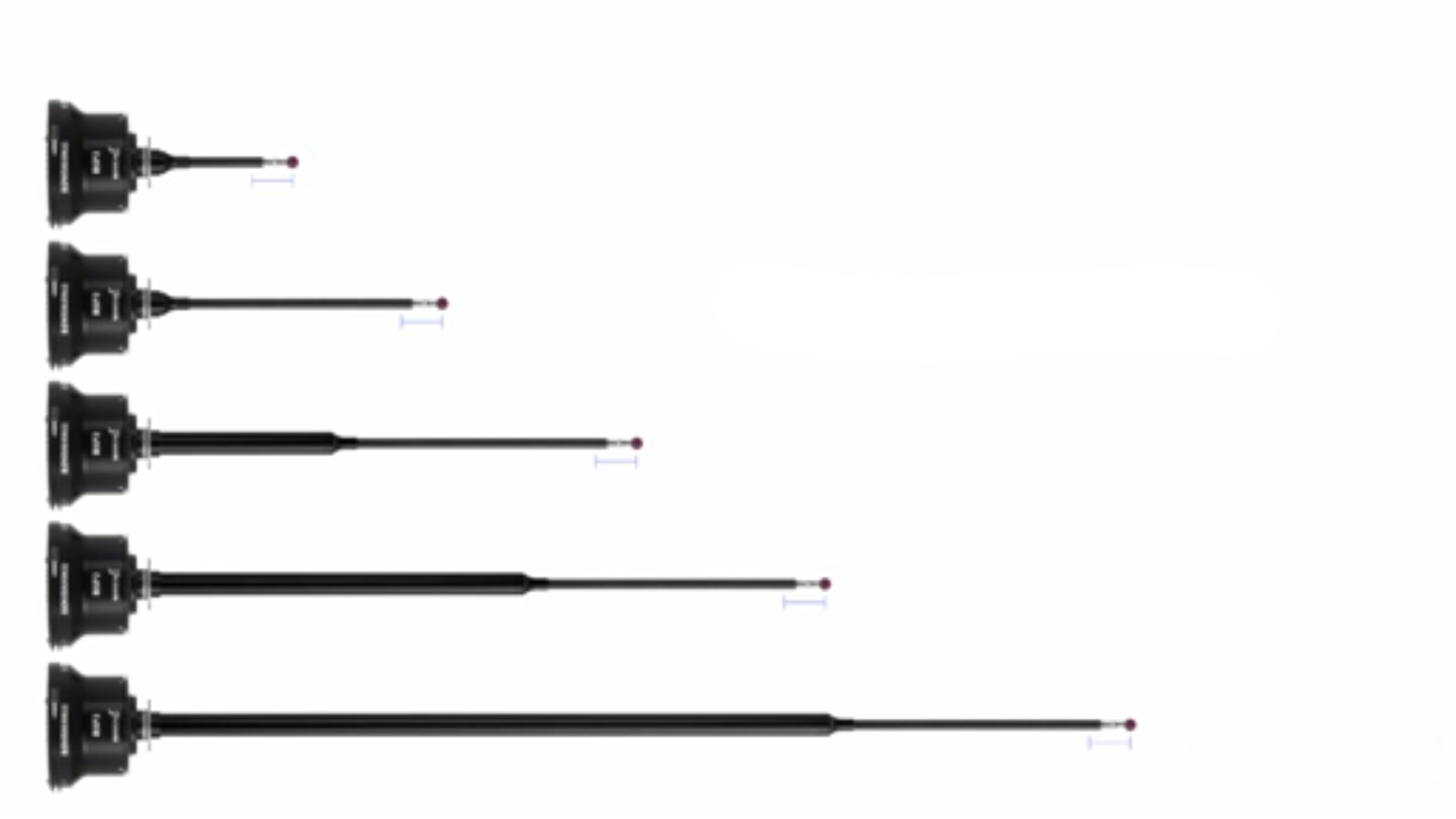

The Renishaw REVO RSP2 probe is specifically designed for high-speed, high-accuracy tactile scanning within Renishaw’s REVO 5-axis measurement system. Its ability to quickly capture streaming point data makes it ideal for inspecting parts with complex geometries where rapid data acquisition is critical.

Verisurf CMM Programming: Optimizing RSP2 for Speed:

Verisurf CMM Programming takes the high-speed capabilities of the REVO RSP2 even further by providing:

Efficient Scan Path Planning: Verisurf’s software allows users to create optimized scan paths that minimize probe movement and maximize data capture rate. This reduces overall scanning time without sacrificing accuracy.

High-Speed Data Processing: Verisurf is designed to handle the large volumes of data generated by high-speed scanning with the REVO RSP2. Its efficient algorithms ensure rapid processing and analysis, providing quick feedback on part quality.

Dynamic Measurement Capabilities: Verisurf enables dynamic measurements while scanning, allowing for real-time analysis of critical features. This further accelerates the inspection process by eliminating the need for separate point-to-point measurements.

Collision Avoidance: Verisurf’s software incorporates advanced collision avoidance features that help protect the REVO RSP2 probe during high-speed scanning operations. This can prevent costly damage and ensure uninterrupted inspection.

Automated Reporting: Verisurf automates the generation of detailed inspection reports from high-speed scan data. This saves time and reduces the potential for human error in data analysis and reporting.

Applications of Verisurf and REVO RSP2 High-Speed Scanning:

- In-line inspection: Fast and accurate measurements on the production line to ensure real-time quality control.

- Large part inspection: Quickly capturing data from large components like automotive or aircraft structures.

- Reverse engineering: Rapidly acquiring point cloud data for creating digital models of physical parts.

- Inspection of parts with many features: Efficiently measuring a high volume of features in a short amount of time.

The Renishaw REVO RSP2 is a powerful tool for high-speed CMM scanning, and Verisurf CMM Programming is the key to unlocking its full potential. By providing optimized scan path planning, high-speed data processing, and automation capabilities, Verisurf enables manufacturers to achieve faster, more efficient, and more accurate inspection results. This combination empowers them to meet the demands of modern manufacturing and maintain a competitive edge.