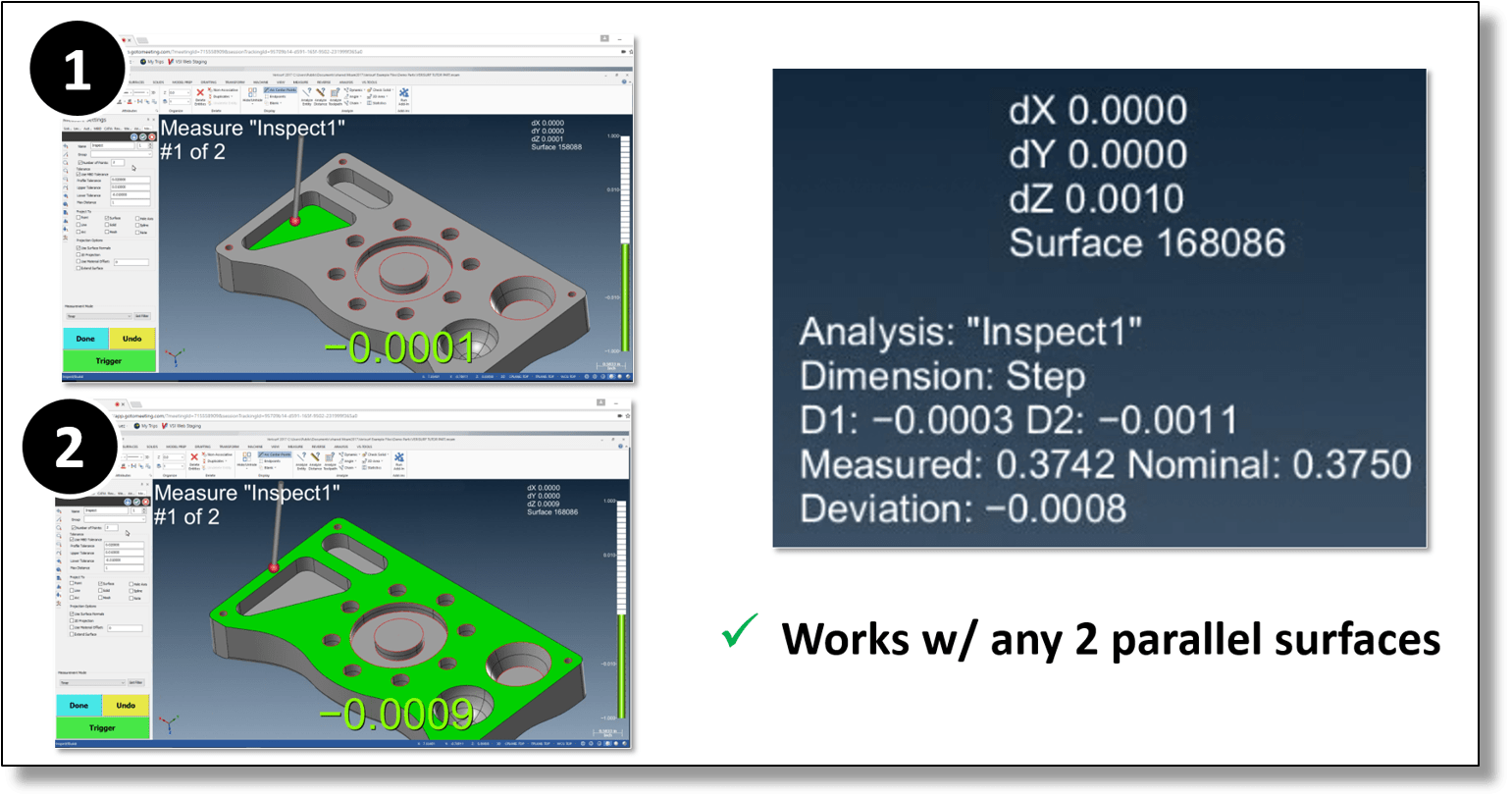

Leveraging 2-Point Analysis means no more constructing sets of planes to measure 2D distances. Verisurf’s new 2-point Analysis functionality lets you measure length, width, height, step, flush, or gap on any set of parallel surfaces with only 2 measurements. The displayed results show dimension type, measured value, and nominal value – providing a quick way to get a nominal dimension without dimensional annotations or additional computations from a separate paper drawing.

Calculating Actual Step Values Before 2-Point Analysis

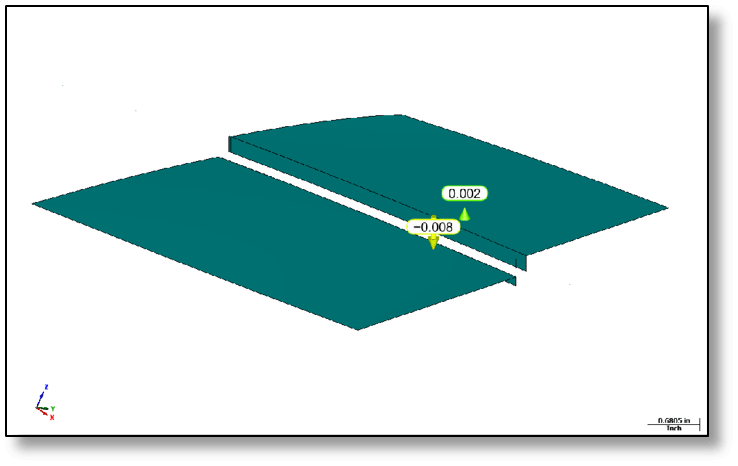

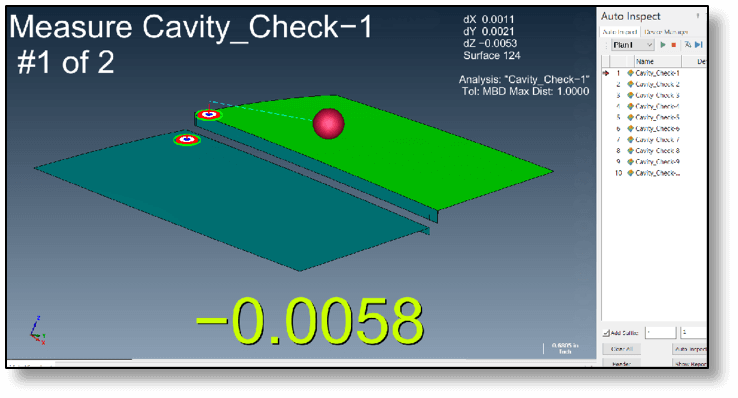

In previous versions capturing an actual step value would 2 measurements on adjacent surfaces while saving 2 separate Analysis Objects. Once the results are captured the data is then moved from the shop floor into post-processing. To determine the actual Step value using only the 2 surface deviations, the sum of the two numbers would be added to the known nominal step value. In the below image, it is known that the nominal step is .312”.

Since the -.008” deviation on the lower portion of the step indicates the surface is too low and the.002” deviation on the top surface is too high we know the step is .010” too large and can add this number to the .312” nominal making the actual step value.322”. This method is then repeated for each pair of steps recorded, proving to be time-consuming for large inspection jobs in addition to being prone to human error.

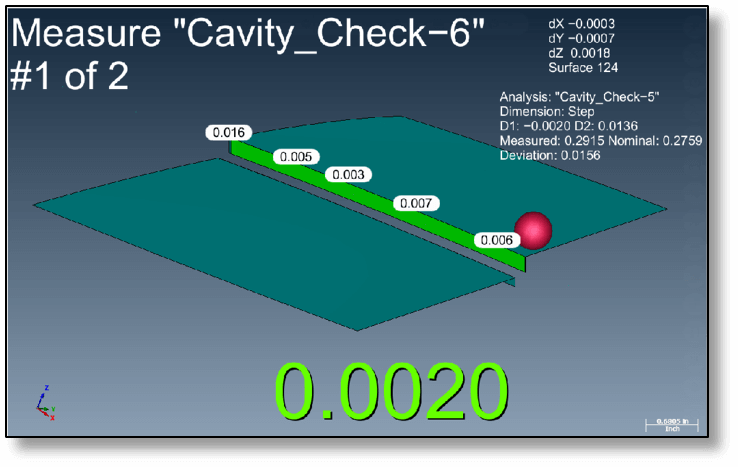

During repairs of cavity depths or panels with excess material, the same method was also used to calculate actual step values in real time while an airframe mechanic removes the material. Large repairs were also found to be time-consuming as any progress made from the material removal would be checked incrementally by the quality technician.

Calculating Actual Step Values with 2-Point Analysis

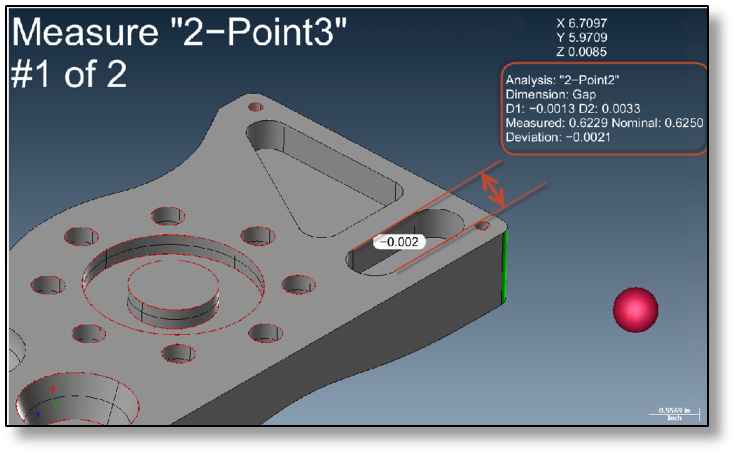

Verisurf 2-Point analysis is enabled when the Build/Inspect dialog is set to measure 2 points. Using the same method to capture 2 adjacent points as above, the operator can record points as needed. Instead of saving the individual surface deviations, Verisurf automatically saves the Shim values by utilizing the CAD nominals. In the image seen below, the same panel is measured in 5 locations in only a matter of seconds, completely removing any input error from the technician. The on-screen Info Text also shows the individual analysis summary along with the Actual and Nominal Step Values.

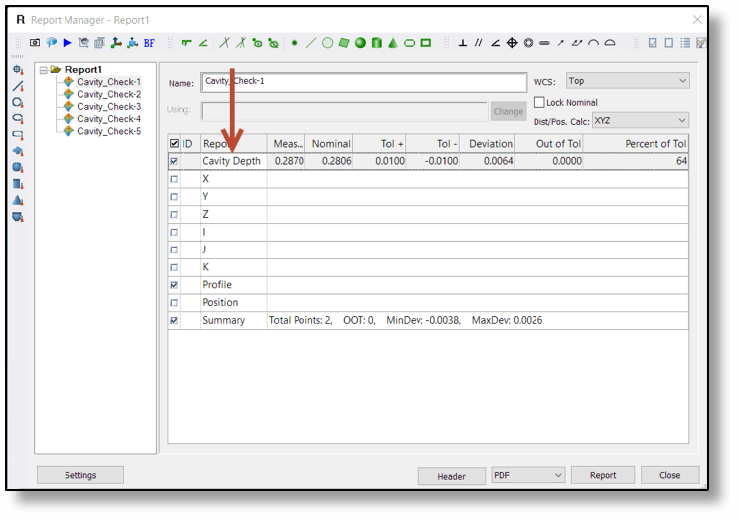

Other Benefits and Uses of 2-Point Analysis

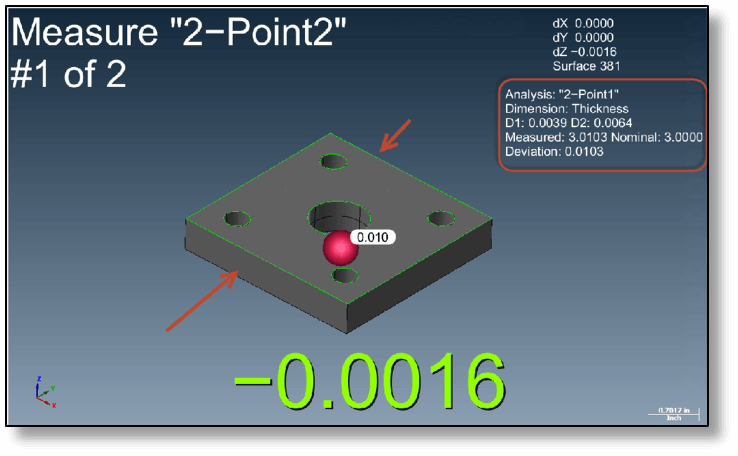

A major advantage of 2-Point analysis is the ability to leverage an auto-inspect plan since they share the same reporting properties as regular analysis objects.

Since the location of the CAD step value is determined from the location of the measured analysis pair, tapered or chamfered steps will not affect the measurement integrity.

The ability to quickly inspect 2D dimensions and Gaps is also available depending on the probe normal during the measurement. If both points have similar normals, Verisurf will calculate a Step, when 2 points have opposite facing normals, Verisurf calculates Thickness (distance) and when facing each other,

Verisurf Software, Inc.

Verisurf Software, Inc. is an advanced three-dimensional measurement solutions company committed to delivering advanced computer-aided inspection and reverse engineering solutions. Verisurf software helps manufacturers of all sizes and industries produce higher quality products in less time and at a lower cost with automated, Model-Based Inspection processes. For more information, visit the Verisurf website at https://verisurf.com.