Sheet Metal Parts Inspection with the

Quantum X FaroArm® Series

Powered by Verisurf

THE COMPLETE SOLUTION

Inspection & Analysis with Quantum X FaroArm® Series and Verisurf Software

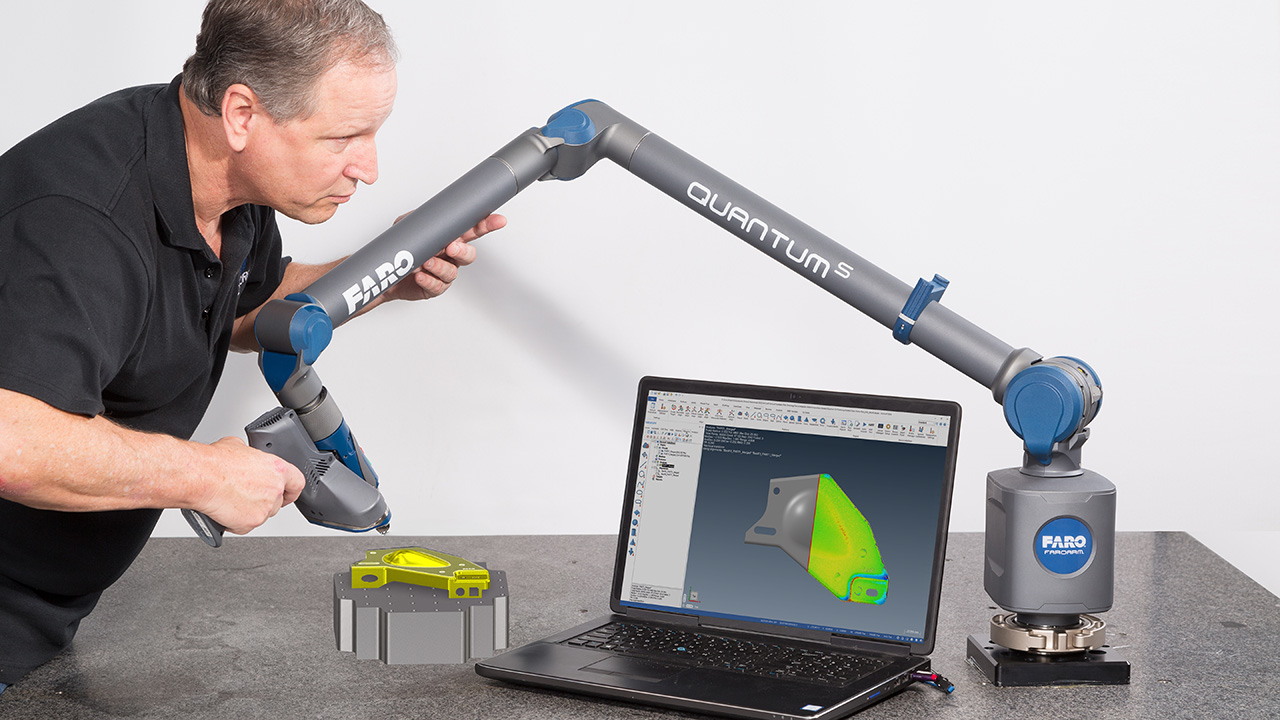

The Quantum X FaroArm® Series powered by the Verisurf Inspection & Analysis Suite of software, is a complete metrology solution that empowers inspection and quality reporting on sheet metal parts with maximum effectiveness and efficiency. This unique application involving stamped, formed, or fabricated sheet metal, often with complex contours made by sophisticated tooling, is well-suited to the combination of scanner and tactile probe.

When a manufacturer wants a single system that can do the entire job, is efficient, easy to implement, and easily learned by technicians, the Quantum X FaroArm+scanner with Verisurf software is perfect solution.

For in-process inspection between steps along the production cycle, and for first article inspection or final buy-off, it can all be done with this single solution and one minimally-trained operator.

With Verisurf software and the Quantum X FaroArm® Series, there are numerous capabilities and efficiencies provided:

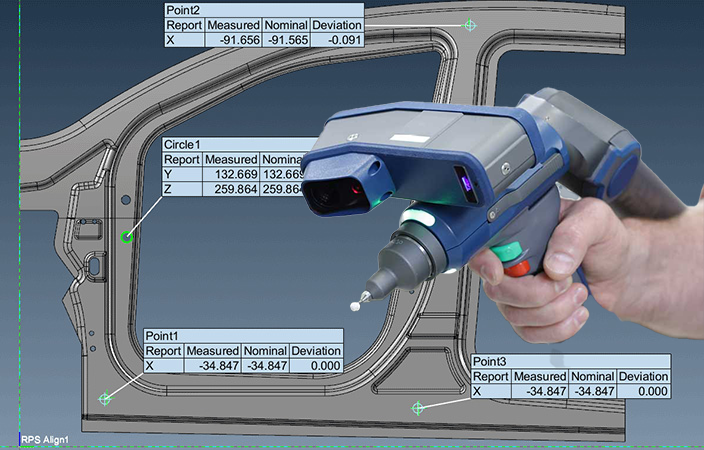

- With the hard probe, measure precise datum alignment target locations and critical hole and slot positions.

- Measure non-line-of-sight, closed features with standard or extended contact probes.

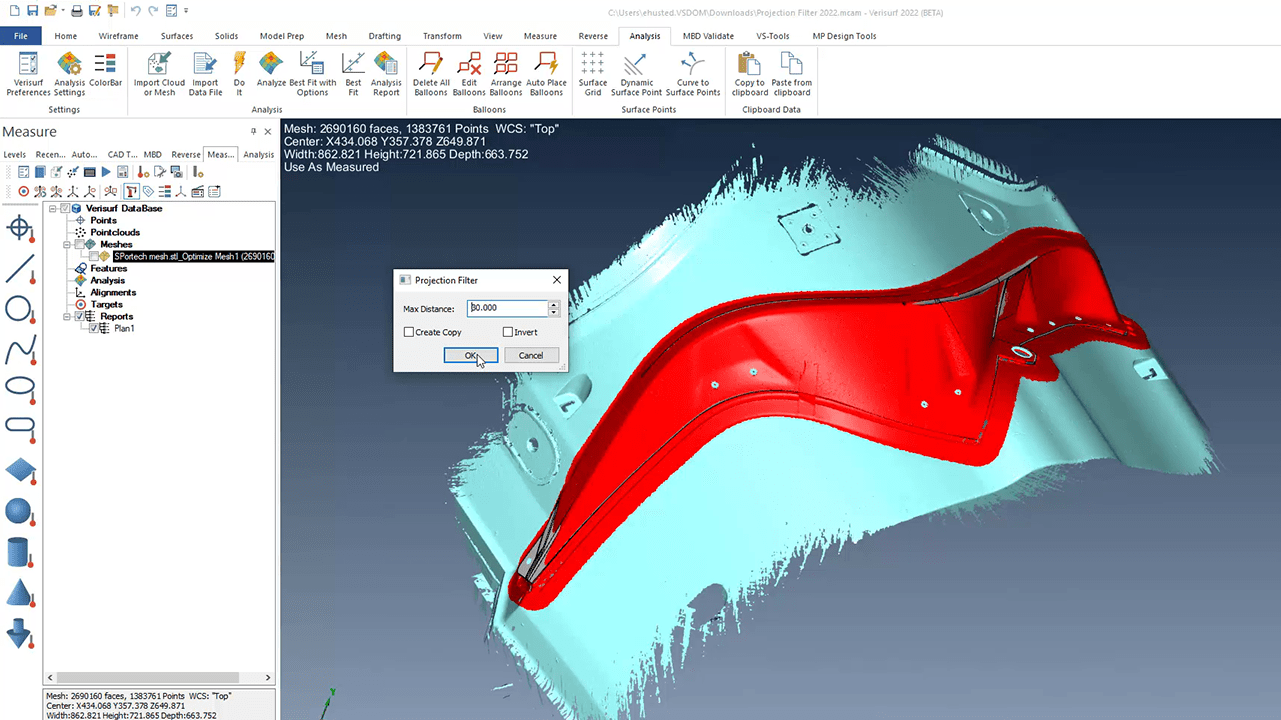

- With the flip of a switch change from probe to scanner for super-fast surface profile data capture, providing complete part coverage including contours, fillets, blend radii, and other exposed features.

Check out our article on RPS Alignment, especially relevant in the automotive industry.

- Scan coverage details every millimeter of the part providing critical information on part deformation from stamping, hydroforming, or other sheet metal technologies.

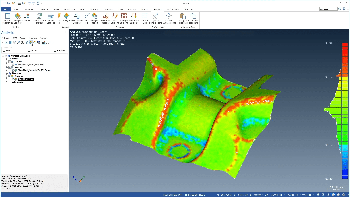

- Engineers require fine detail provided by surface profile color maps which highlight radii showing them to be fully formed or require tweaking of the tooling.

Deviation analysis provides necessary information for tooling development

Use Verisurf AUTOMATE to sequence the entire inspection for exacting process control and efficiency from part to part.

Quantum X FaroArm® Series Basic Specifications

Quantum X comes with five length options and three accuracy performance levels each, and with multiple laser line probes that address various non-contact measurement needs.

- The FARO Quantum X FaroArm Series is part of FARO’s portfolio of portable measurement arms, offering up to a 15% increase in accuracy over comparable previous generation models.

- Designed to probe or scan, articulated measurement arms are significantly more adaptable than bulkier fixed CMMs.

- The series features easy-to-operate, simple-to-learn articulated measuring arms designed as an all-in-one solution for those who are first becoming familiar with the benefits that portable CMMs provide, and other users who are looking for market-leading accuracy.

- The right Laser Line Probes (LLP) is not always a “one size fits all” choice. With the Quantum X Series, choosing the right LLP for you is seamless. Unique LLPs help boost productivity collectively or individually.

FAROBlu Laser Line Probes

The range of Laser Line Probes (LLP) as an attachment add-on ensures maximum efficiency for a variety of needs: from large area fast scanning to high-accuracy, non-contact measurement of small features. FARO’s Laser Line Probes turn the FaroArm into a hybrid system that enables contact-less scanning and touch probing in one device – either from initial purchase or as a future buy, based on evolving business needs.

FAROBlu® xR – Maximize scanning resolution and accuracy

This Laser Line Probe is ideal for high-precision tasks with tight tolerances to capture data at highest accuracy and best resolution possible. Users can scan small intricate parts and fine details with 1.5 times the accuracy, improving production quality with better and more reliable data.

FAROBlu® xP – Scan more productively

This Laser Line Probe offers the ability to scan anything with a balanced blend of accuracy, speed and coverage—increasing profitability and throughput with performance suitable for any application.

FAROBlu® xS – Significantly increase scan speed

This Laser Line Probe is best for large parts or expansive surface areas when data collection speed is top priority. The extrawide laser stripe delivers double the coverage in a single pass, allowing users to collect data up to 2.6x faster than the xR and 1.6X faster than the xP. Fewer passes to collect data means faster results and higher productivity.

FARO 8-Axis Max

The integrated 8-axis rotary worktable is a unique manufacturing solution that decreases scanning and probing time by up to 40%, while maintaining accuracy. The rotary worktable is available with all Quantum X FaroArm Series models.

Verisurf INSPECTION & ANALYSIS SUITE

- Flexible best fit options reduce scrap and rework

- Embed stunning color results in your reports

- Connect to any portable arm, tracker or scanner

- Fastest align-inspect-report

- Measure any 2D or 3D feature type

- Memorize steps to create reusable plans

- Full MBD (GD&T) import and annotation

- Compare as-built to any nominal CAD source

- Advanced best fit increases conformance rates