A Practical Approach to Advanced Manufacturing Education at Van Buren Tech

Van Buren Tech (VB TECH), Lawrence, Michigan, is an innovative Career and Technical Education (CTE) institution. As an affiliate of the Van Buren Intermediate School District, VB TECH offers a practical approach to education, instilling in 11th-12th grade high school students the confidence to prepare for a variety of postsecondary career options. VB TECH is part of a statewide CTE initiative focused on helping students earn industry-recognized credentials and allowing them to receive college credit that transfers to multiple colleges and universities.

Gabe Kooyers (right), Vanburen Tech Advanced Manufacturing program instructor and President of the Michigan Machine Tool Instructor Association with Titan Gilroy (left), founder, CEO, and president of TITANS of CNC and the online training platform TITANS of CNC: Academy, during a recent shop visit.

Gabe Kooyers, the VB TECH Advanced Manufacturing program instructor and President of the Michigan Machine Tool Instructor Association, has been instrumental in the program’s success at the state and school levels. Gabe has been part of a statewide committee that includes other CTE instructors tasked with reviewing and recommending a Machine Tool curriculum for the state of Michigan. The Michigan CTE initiative is rapidly gaining recognition as one of the most successful in the nation due to its objective-based and practical approach, combined with both instructor and state-level collaboration.

In a practical shop environment, students learn how to program, prep, cut, and inspect parts using commercial software, CNC machines, and other tools.

Instead of working from the top down and implementing a standard CTE program, the Michigan Department of Education chose a bottom-up approach through its office of CTE. In 2022, the collaborative effort began between the state of Michigan and its CTE instructors, along with representatives from business and industry, to better align coursework with industry needs. Over nine months, industry professionals representing OEMs and tiered suppliers serving the automotive, aerospace, and general manufacturing industries completed in-depth workforce development surveys. Collectively analyzing the data was pivotal in developing a program and curriculum that best-served students, met Federal Perkins V requirements, and served the economic interests/needs of the State. This approach established the framework so that programs could produce students with applied skills relevant to industry needs.

“This was a great unifying step forward for CTE programs across the state,” according to Kooyers. “Our machine tool program at VB Tech has existed since 2003 and evolved based on lessons learned. This was effective but still internally focused and lacked broad collaboration of best practices, a challenge realized by virtually every instructor in the state.”

With the Michigan CTE machine tool curriculum on a solid, unified footing, VB TECH and other CTE schools across the state could further align their programs and move forward, applying experience, best practices, and creativity to engage students in the best way possible. This unwavering commitment to providing an engaging learning experience has proven to inspire and excite potential students about the depth of opportunities in manufacturing.

Applied Project-Based Learning

Redesigning the Advanced Manufacturing Program at VB Tech required more than understanding the wants and needs of the industry. Federal and state guidelines also needed to be adhered to, and the necessary curriculum had to align with established CIP (Classification of Instructional Programming) codes. The approved strategy was to anchor the program with a solid, applied, project-based learning platform from which there are many high-quality programs to choose from.

The Titans of CNC Building Blocks curriculum supports instructor-led, project-based learning programs and allows students to advance at their own pace.

Following an extensive review, the Titans of CNC Building Blocks curriculum for CNC Expert Credential best aligned with the program goals and fulfilled the necessary CIP code requirements. After an extensive planning period that included many stakeholder meetings, the state of Michigan adopted the committee’s recommendation and has since listed Titans of CNC and CNCEXPERT as approved credentials that can be used for Career Technical Education (CTE) Machining programs in Michigan.

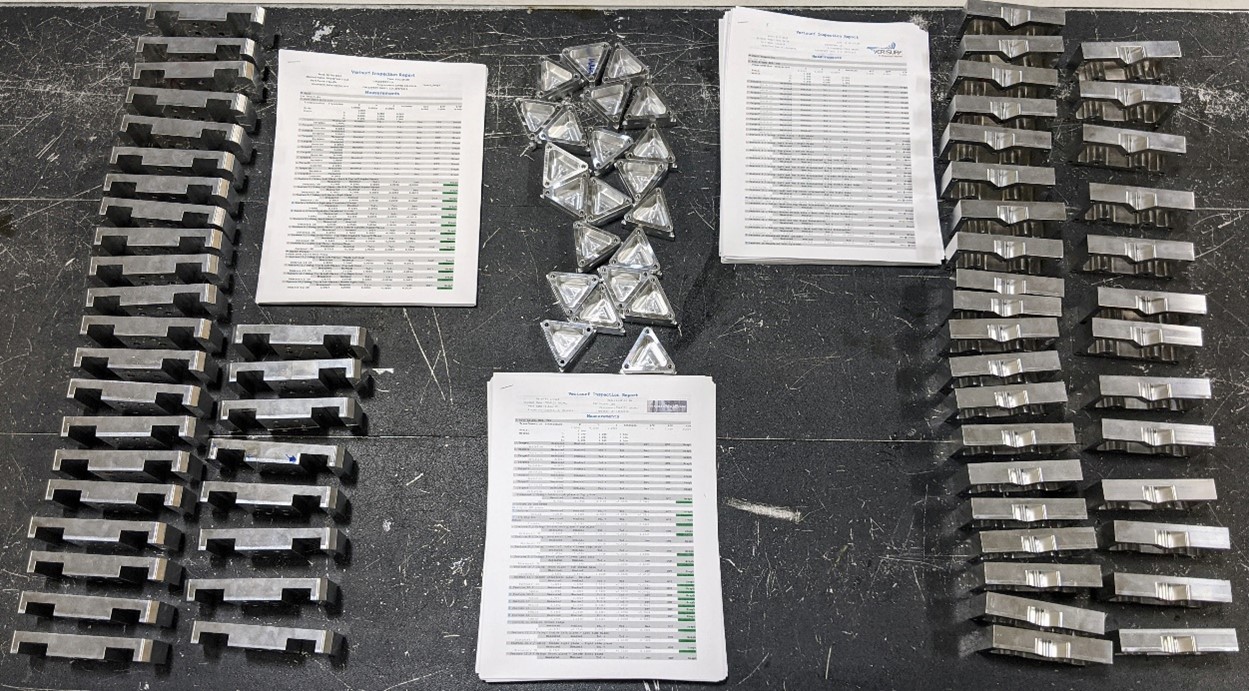

The Titans of CNC Building Blocks is an educational build series designed for 3-axis mills. This ten-part series aims to teach students how to design, program, and complete parts that meet print specifications. Under the VB TECH Advanced Manufacturing program, students can complete all ten of the Titans of CNC Building Blocks series, earning the following industry-recognized certifications along the way:

- Complete Building Blocks 1,2,3,4

Titans of CNC Mill Level One Credential - Complete Building Blocks 5,6,7,8

Titans of CNC Mill Level Two Credential - Complete Building Blocks 9,10

Titans of CNC Mill Level Three Credential

Under the Van Buren Tech Advanced Manufacturing program, students can complete all ten of the Titans of CNC Building Blocks series, earning industry-recognized certifications.

“The Titans of CNC program has proven to be an excellent fit for participating CTE schools throughout Michigan. The Titans of CNC Building Blocks curriculum is a good match for the established Machine Tool CIP Code; the content volume is excellent, and it has an engaged social community. We are in the process of building out our next CTE program, CNC Lathe Credential, and will be using the Titans Rocket Series to support the curriculum,” said Kooyers.

Staying on Point

The VB TECH credo is “Your Career. Your Future. Your Life. Gabe Kooyers effectively emphasizes this embodiment to his students by treating them as adults and expecting the same in return. When the shop is in session, it is all about learning skills and solving problems. These traits will help students in the workplace and in life. Gabe’s five pillars of employment success, from fast food to aerospace, hang on the VB TECH shop wall as a constant reminder. “I tell students every day, if you don’t follow the five pillars, you might get a job, but you won’t keep it,” said Kooyers.

- Show up every day

- Work the whole time you are there

- Have a willingness to learn

- Have a good attitude

- Pass a drug screen

Keeping a Pulse on the Program

VB TECH delivers the Titans of CNC curriculum using applied project-based learning. This combines theory with practical hands-on experience, producing real-world parts. Although this sounds straightforward, the program required fine-tuning after its initial launch. “I started teaching Titans of CNC Building Blocks Academy curriculum in 2016. Back then, I felt the right approach was to start with manual tools and work up to CNCs,” said Kooyers. “It turned out I was wrong and had difficulty keeping students engaged. So, I flipped the course to start with CNCs and worked backward to incorporate manual milling, and the students were much more engaged. The program has been very successful ever since. We must remember that kids today have grown up with technology and are not afraid of it.”

Industry 4.0 and the proverbial Internet of Things (IoT) continue to drive advanced manufacturing. Mandatories such as digital continuity, digital twins, universal compatibility, Product Lifecycle Management (PLM), Statistical Process Control (SPC), and open communications across the manufacturing enterprise are quickly becoming the rule, not the exception. “At VB TECH, technology is at the forefront in teaching advanced manufacturing. “We rely on a mix of instructional delivery that includes instructor-led teaching, Internet-based tutorial training, and practical hands-on project-based learning, all with as much access to technology as possible. This is now what advanced manufacturing in the real world is all about,” added Kooyers.

Automated Model-Based Inspection and Reporting

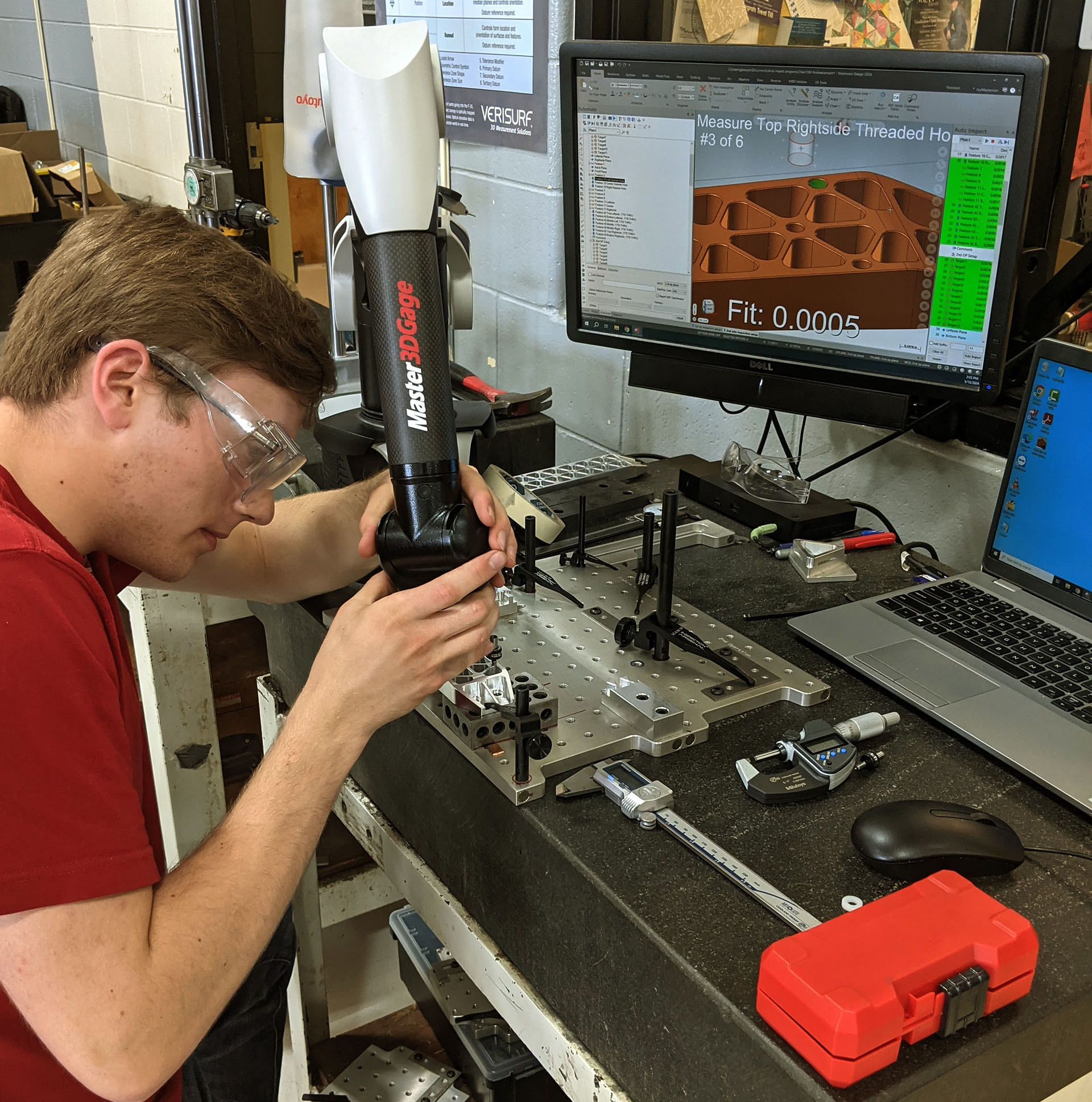

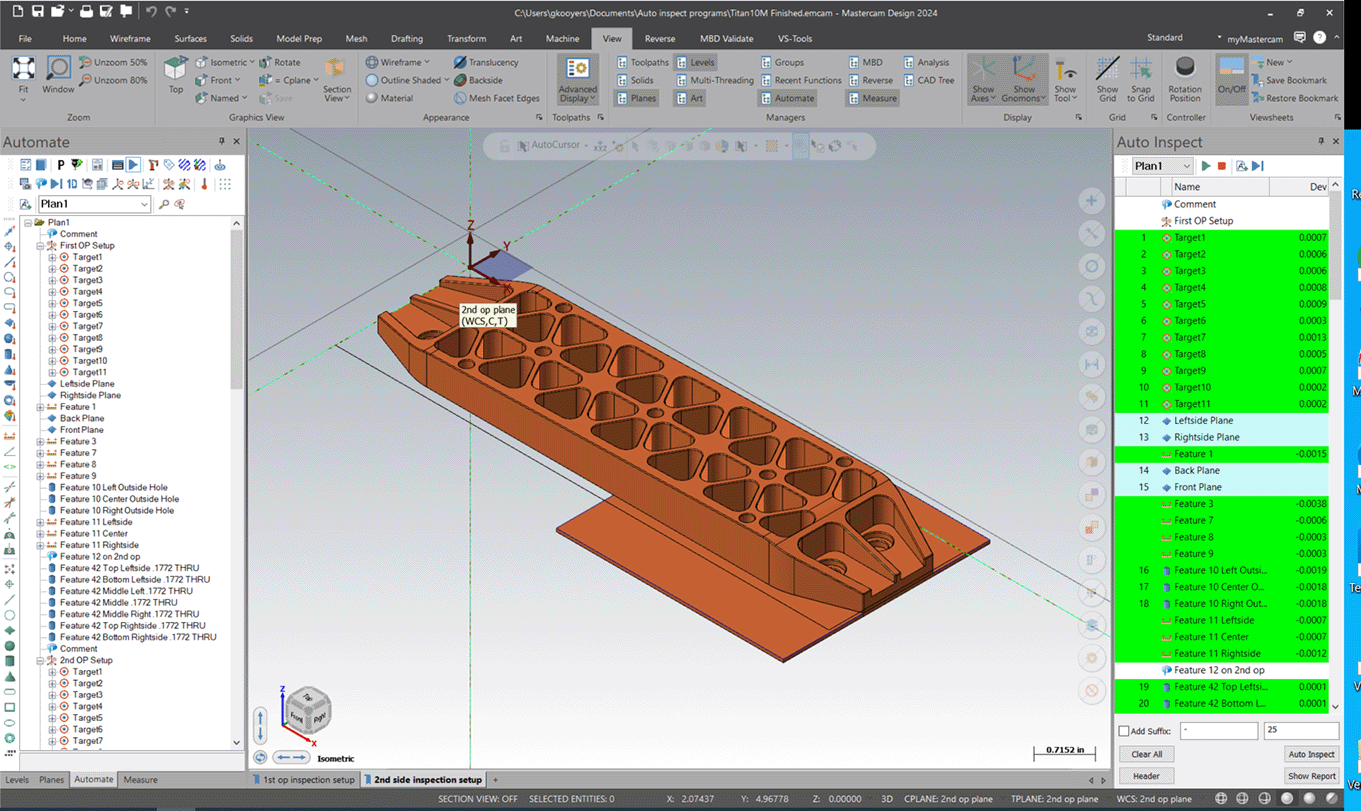

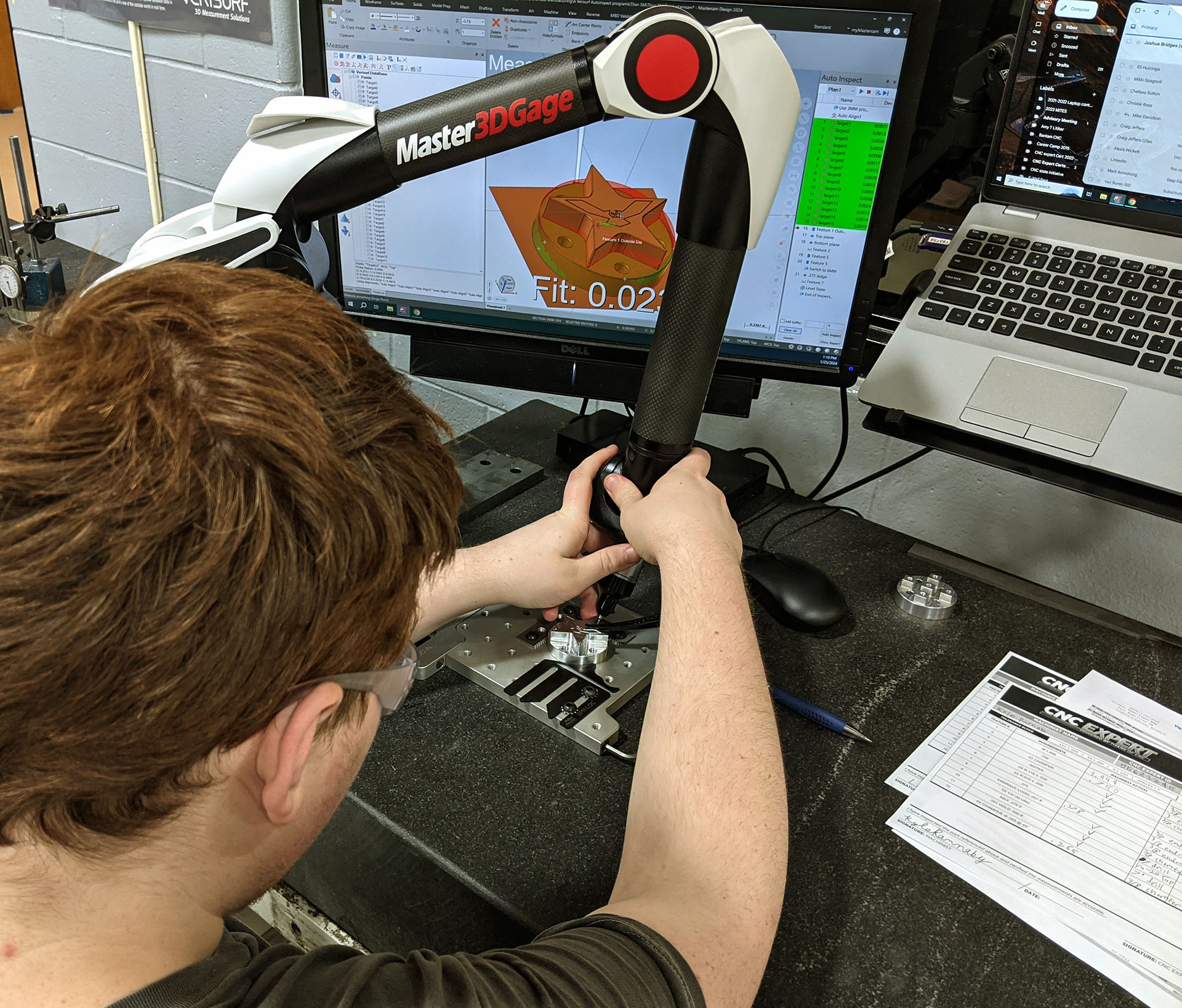

“We introduce students to Mastercam CAD/CAM software, which is our preferred teaching software. Mastercam is committed to education and is the world’s most widely used CAD/CAM software,” said Kooyers. “We also want students to think about maintaining a digital thread throughout the manufacturing process, so we have implemented Computer Aided Inspection (CAI) using Master3DGage, Powered by Verisurf Software.”

Verisurf inspection software is model-based and uses the same intelligent 3D CAD model data used to program and cut the part, maintaining a consistent digital thread throughout the process.

: Following production, students inspect their own parts using a Master3DGage solution powered by Verisurf software. Instructor-generated inspection routines maintain repeatable process control and monitoring, like in a commercial shop.

Verisurf software is built on the Mastercam platform and can be initiated right from the Mastercam tool menu. This enables optimized, time-saving workflows with repeatable process control, a central tenet of quality management. Verisurf is committed to intelligent Model-Based Definition (MBD). MBD allows students to perform metrology workflows in a seamless CAD/CAM environment and maintain model-based digital continuity. Like Mastercam, Verisurf is powerful software used in industry and education. It supports all CMMs, 3D scanners, optical trackers, and arms to measure and collect data for metrology applications.

Master3DGage is an affordable and portable turnkey rapid 3D inspection and reverse engineering solution that increases efficiency, improves part quality, and reduces scrap. The complete hardware/software solution delivers automated ‘in-process’ inspection to the shop floor, providing first article inspection and reporting in minutes.

“The Master3DGage solution demonstrates to students the need to close the loop in digital manufacturing workflows,” said Kooyers. “For now, we are teaching the benefits of a 3D model-based workflow from CAD to CAM to CNC to Computer Aided Inspection. Sometime later, we could add a curriculum on reverse engineering parts or features into the 3D model-based process by adding an optional plug-n-play non-contact laser scanner.

The Master3DGage measurement and inspection package offers highly accurate and powerful toolsets that are easy to learn and operate, using a quick three-step workflow:

- Align the manufactured part to the 3D CAD model by probing corresponding alignment targets on the virtual model

- Inspect manufactured parts in real-time by probing any surface or by following repeatable automated inspection plans

- Report inspection results in industry standard formats with intelligent GD&T and real-time color deviation maps for clear and practical analysis

The Master3DGage inspection solution helps instructors reduce administrative bottlenecks. In the cited example, the instructor saved more than 20 hours a week inspecting parts, which allowed more time to be spent in the shop working with students.

“As the instructor, I can quickly and easily pre-program the inspection routines in Verisurf for each test part. The students can then Align, Inspect, and Report their finished parts. I can then verify each inspection and complete the Inspector Verification Form for submission and certification,” said Kooyers. “The students gain exposure to in-process inspection and reporting, and I save more than 20 hours a week in administrative time measuring and grading parts. This is time I can put right back into the shop working with students. It’s a win-win.”

Best Practices Peer Review

The Michigan Machine Tool Instructor Association members meet periodically as a peer group to discuss challenges and best practices. Topics covered to ensure the statewide programs are in sync and on track include employability skills, interpersonal skills, equipment use and needs, setting up grade books, and deployment of the Titans of CNC Building Blocks.

A recent Michigan Machine Tool Instructor Association meeting to discuss challenges and best practices.

“During a recent best practices review, I was approached by an instructor overwhelmed by the administrative bottlenecks, specifically, inspecting and grading completed parts. He had 33 parts, each requiring 15 minutes (over 8 hours) to inspect and grade. We reduced that time to just 4 minutes each (less than 2 hours) using the Master3DGage,” said Kooyers.

The Advanced Manufacturing CTE program at VB TECH was designed to fill the void left by the elimination of traditional high school shop classes. In part, It was also designed to meet the needs of business/industry as it relates to training highly skilled workers. The result was that, plus a whole lot more. Today, students are looking at trades as a viable career opportunity, either through direct entry or as a part of a college track. 16-18-year-old students carefully consider these life decisions, and every CTE institution is responsible for providing the best instruction. Manufacturers often hire VB TECH students part-time while still in high school. They design and build automation fixtures, operate CNC machine tools, and use today’s most sophisticated manufacturing and metrology software. Today’s CTE programs serve the developing workforce and industry alike, providing a path forward.

Vanburin Tech https://vanburenisdmi.sites.thrillshare.com/o/VB Tech

Verisurf Software, Inc. https://www.verisurf.com/