MD&M West

February 4-6, 2025

Anaheim Convention Center

Anaheim, California USA

Visit Verisurf booth #3323 in the 3DP CAD/CAM Prototyping pavilion for consultation and demonstrations.

Click HERE for your free expo pass on Verisurf

or enter promo code INVITE975106 when using the show registration form.

The MD&M West Expo

Previously known as Informa Markets Engineering (IME) West, hosting five co-located shows — MD&M West, ATX West, D&M West, Plastec West, and WestPack — we are now merging 4 of these related industry sectors into a single unified show: MD&M West.

WestPack, well-known as the leading event showcasing the latest innovation and excellence in packaging solutions, will be positioned alongside the new Sustainable Manufacturing Expo in the North Hall of the Anaheim Convention Center (just steps from its previous location in Hall A) February 4-5, 2025. Click here to learn more.

Our special focus on your specialty is not changing. One MD&M umbrella unites a community of multiple special interests who all share a single goal – to advance their knowledge, contacts, and progress in the rapidly accelerating world of advanced manufacturing.

Verisurf at the Show

Verisurf will be featuring applications of 3D scanning, CMM programming, reverse engineering, in-process inspection, first article inspection reporting (FAIR), and STL mesh optimization for rapid prototyping, 3D printing, and additive manufacturing. We will demonstrate our interoperability with CAD & CAM systems from Mastercam, SolidWorks, Autodesk, CATIA, NX, Creo, and the popular additive manufacturing 3D formats. We will answer tough questions and demonstrate upgrading the productivity and power of numerous metrology systems from a long list of hardware and OEMs that include API, Coord3, Creaform, FARO, Hexagon, LK, Renishaw, Romer, Scantech, Wenzel, Zeiss, just to name a few.

Shops of all sizes will appreciate inspection in just minutes whether on the shop floor, production work cells, or in the CMM lab. Solve today’s challenges with automation for both collaborative devices and software-automated process optimization for QC and process control.

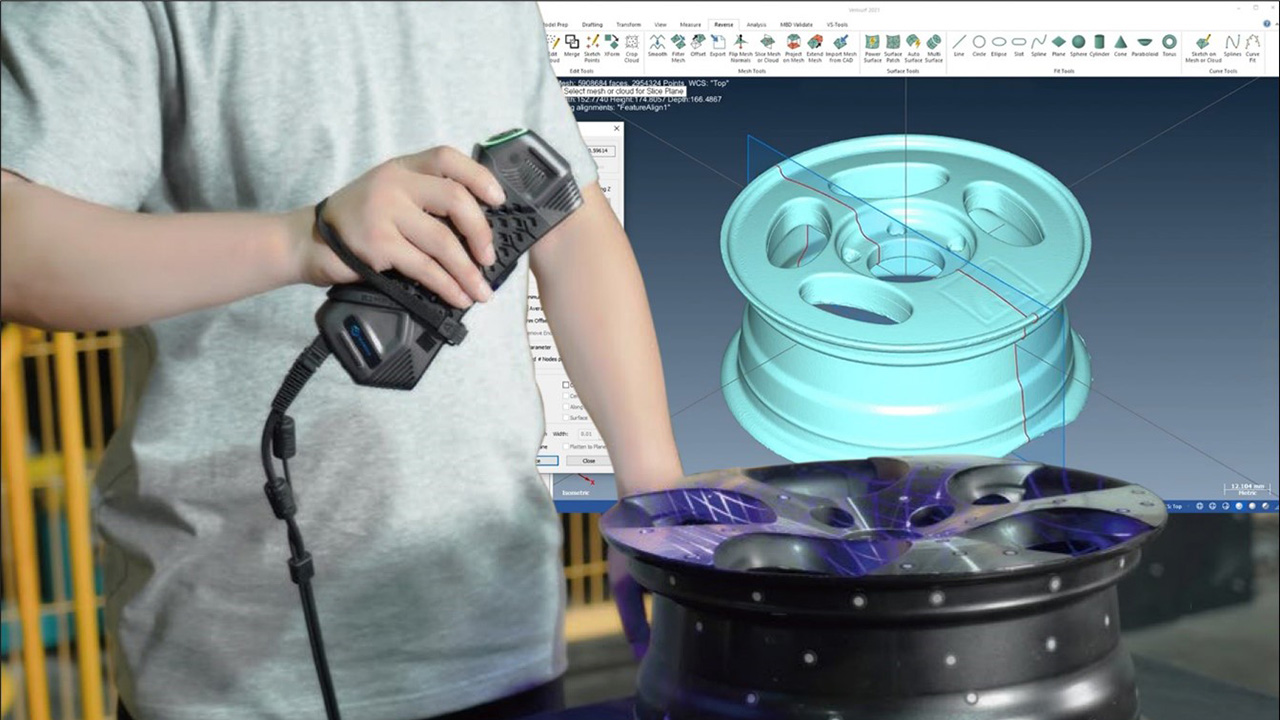

3D Scanning Inspection & Reverse Engineering

Verisurf optimizes both the scanning process and post-processing workflows for both reverse engineering and inspection. Inspection includes automated workflows, automatic feature extraction, full model-based GD&T, and support for all scanning devices. Reverse engineering includes mesh creation, cleanup, filtering, optimization, registration/alignment, and full CAD-supported parametric modeling.

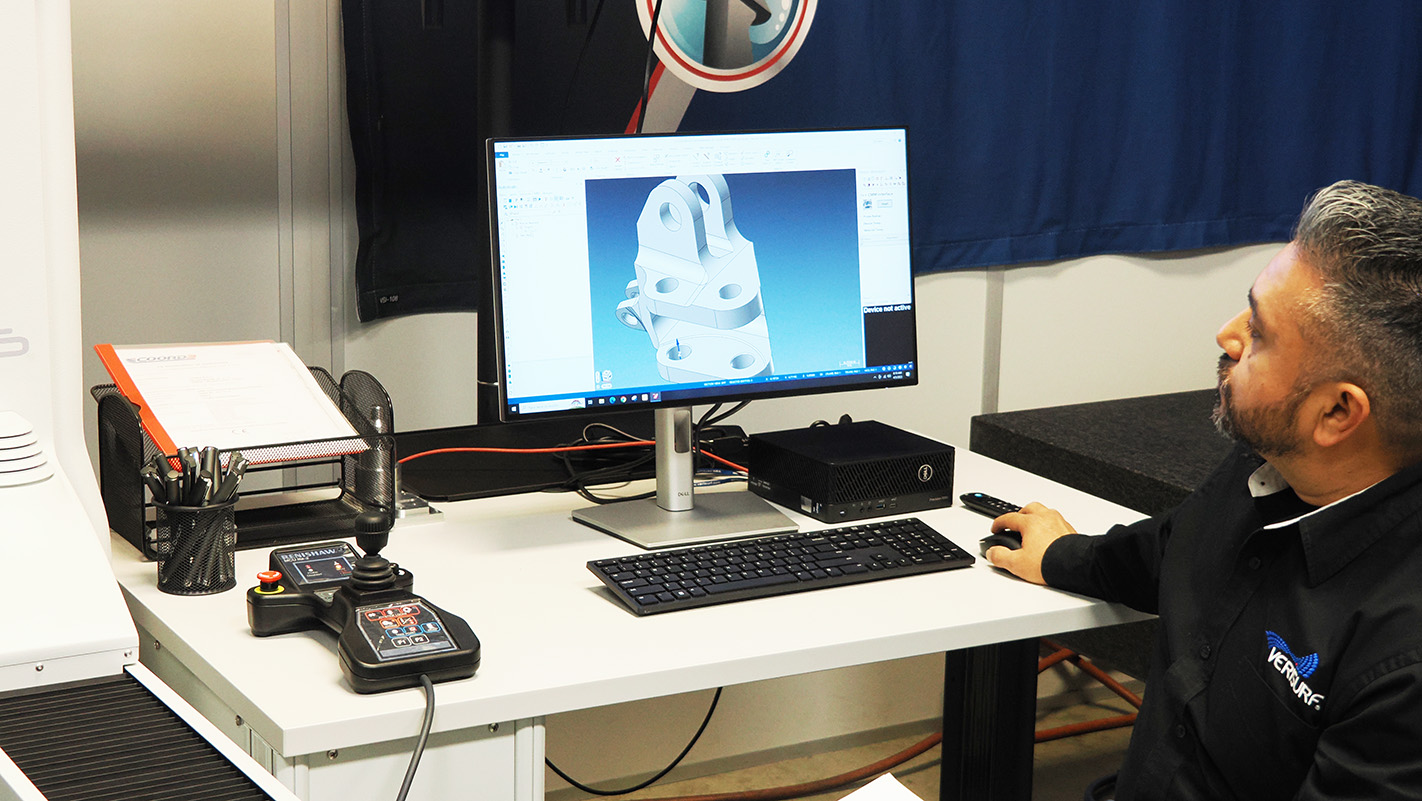

CMM Programming – Productive for All Skill Levels

CMM programming right inside a full CAD/CAM system. Use the same software for your CMM paths that is used for CNC milling machine paths. This is not a rudimentary add-on, it is a high-powered, full-functioning CMM software that programs and operates all brands and types of CMMs, including 5-axis systems. Verisurf replaces many legacy OEM software packages that were designed “old-school” requiring lots of training and expertise to learn complex coding and text editing.

Portable CMM First Article & In-Process Inspection

See how you can vastly improve your first article and in-process inspection jobs in less time and complexity.

The solution also requires considerably less training and experience from the system operators, while minimizing the pre-inspection preparation and setup time.

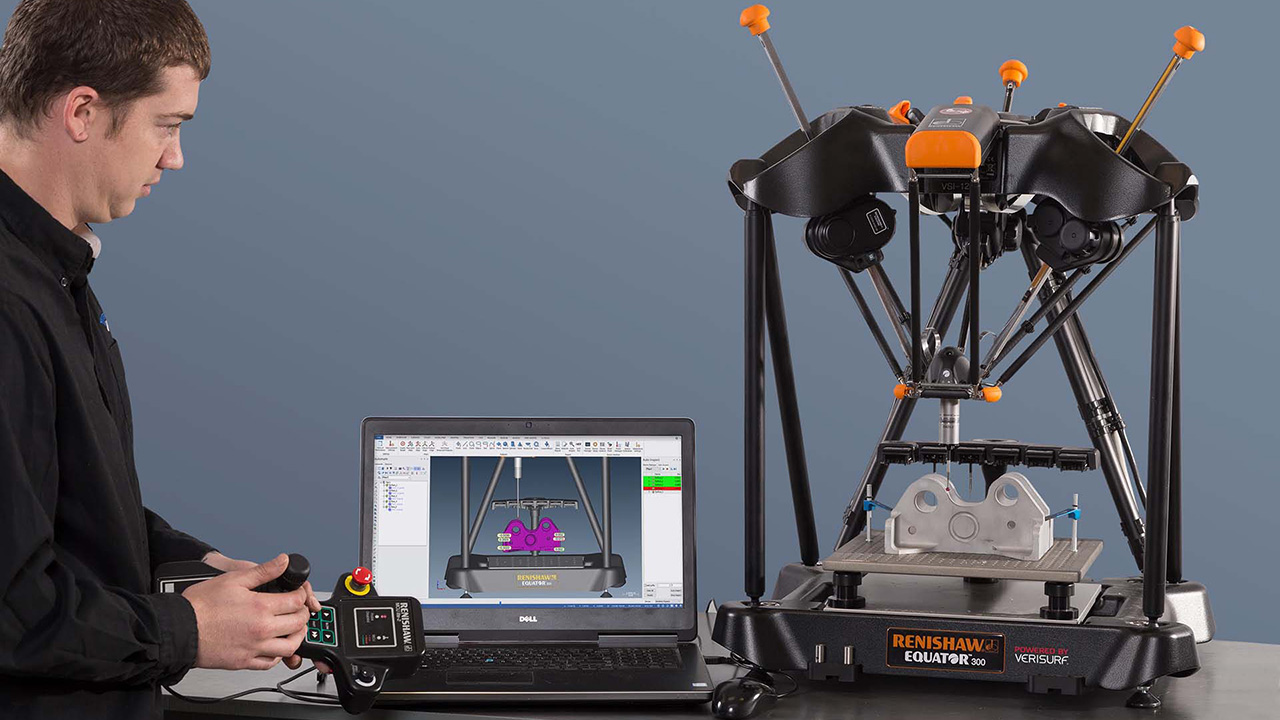

Shopfloor Automated Inspection

The Verisurf CMM Master is an optimized Renishaw® Equator™ automated gauging system upgraded with Verisurf software and volumetric error compensation mapping. This creates a shopfloor CMM that maintains the efficiency of comparator mode but eliminates the extensive mastering process that requires baseline runs on a separate CMM.

Large Volume Field and Industrial Machinery Measurement

Optimize your unique large-volume jobs with modern laser tracker technology and Verisurf software. Do things with one operator that many have to do with two.

Automate the whole process with extremely intuitive, graphical electronic work instructions (program plans) that are a must when you have to work far from the device and computer workstation.

Increased Productivity, 5-Axis CMM Efficiency

Take advantage of the productivity improvements that 5-axis CMMs have to offer. Verisurf adds unique path patterns, programming, and editing features to help users realize a rapid return on their 5-axis investment. Five-axis provides reduced setup time, fewer requirements for special fixturing, and less probe qualification time. Verisurf special features for 5-axis adds even more opportunities for process efficiency and control.

In these days when many manufacturing enterprises are seeing great staffing challenges, our experts can get you up and running quickly and then will support you through the path to excellence.