Digitizing the As-Built Part with the Scantech SIMSCAN 3D Scanner Powered by Verisurf Software

THE COMPLETE SOLUTION

Digitizing the As-Built Part with the Scantech SIMSCAN 3D Scanner Powered by Verisurf Scan Data Suite Software

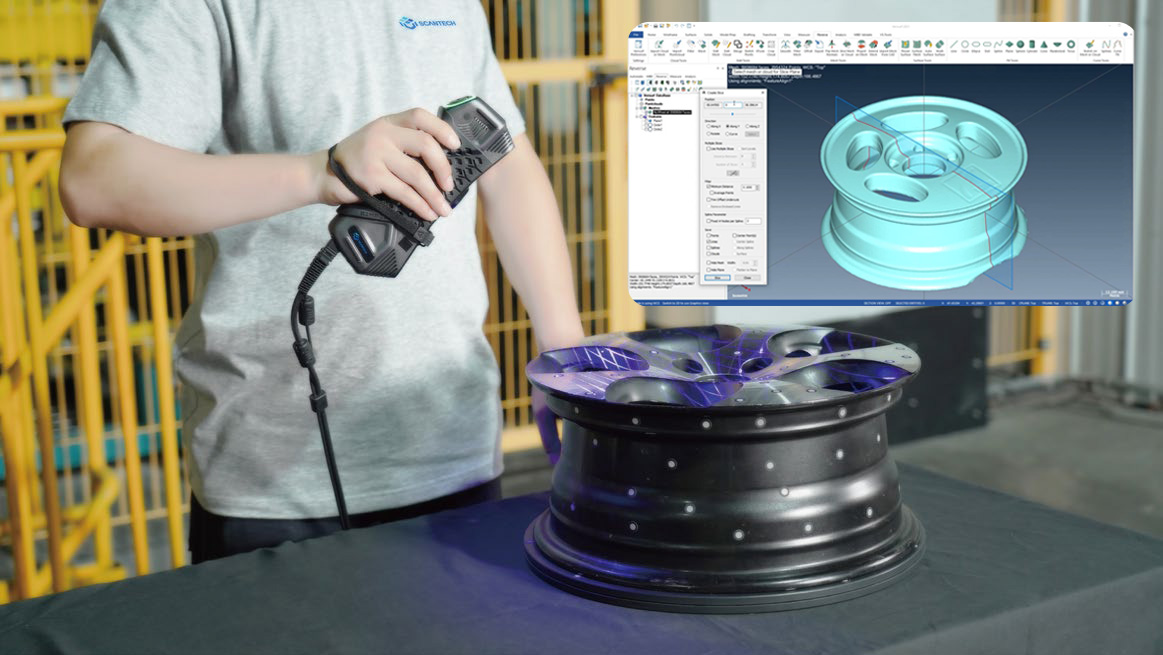

The Scantech SIMSCAN powered by Verisurf Scan Data Suite of software, and optimized by Verisurf training services, is the complete solution for digitizing the as-built part at any point in the manufacturing chain. The model, which reflects the result of upstream production steps to that point, can be used to refine engineering and manufacturing activities reducing complications, time, and money downstream.

Reverse engineering is sometimes called upon to capture the “as-built” condition of a part. Examples include castings or forgings that are purposefully designed to their near-net shape with “plus material” built into the design. Subsequent to initial forming operations, these parts then undergo machining to take them to the final design condition. Similarly, it can be beneficial to utilize an as-built model for stamped sheet metal, plastic, or composite molded parts. Sheet metal springback and molded part warpage create the need to know what the tooling produces so engineers can make accommodations. Another application is when large parts and tools are made with plus material intentional to the design, with the plan to machine to the net shape after forming. Manufacturers reverse engineer these large surfaces so they can program their CNC machines to the as-formed surfaces to save time and money. (see the AIT story below)

The SIMSCAN-Verisurf Process

1. Capture data with Scantech SIMSCAN scanner with the included SCANVIEWER application

- SCANVIEWER is powerful 3D software for scanner operation, reference target capture, management, and alignment

- Provides data capture, visualization, and verification of coverage

- Complete scanning data acquisition in SCANVIEWER with preparation for export to Verisurf (cleanup of data can be accomplished in SCANVIEWER or in Verisurf)

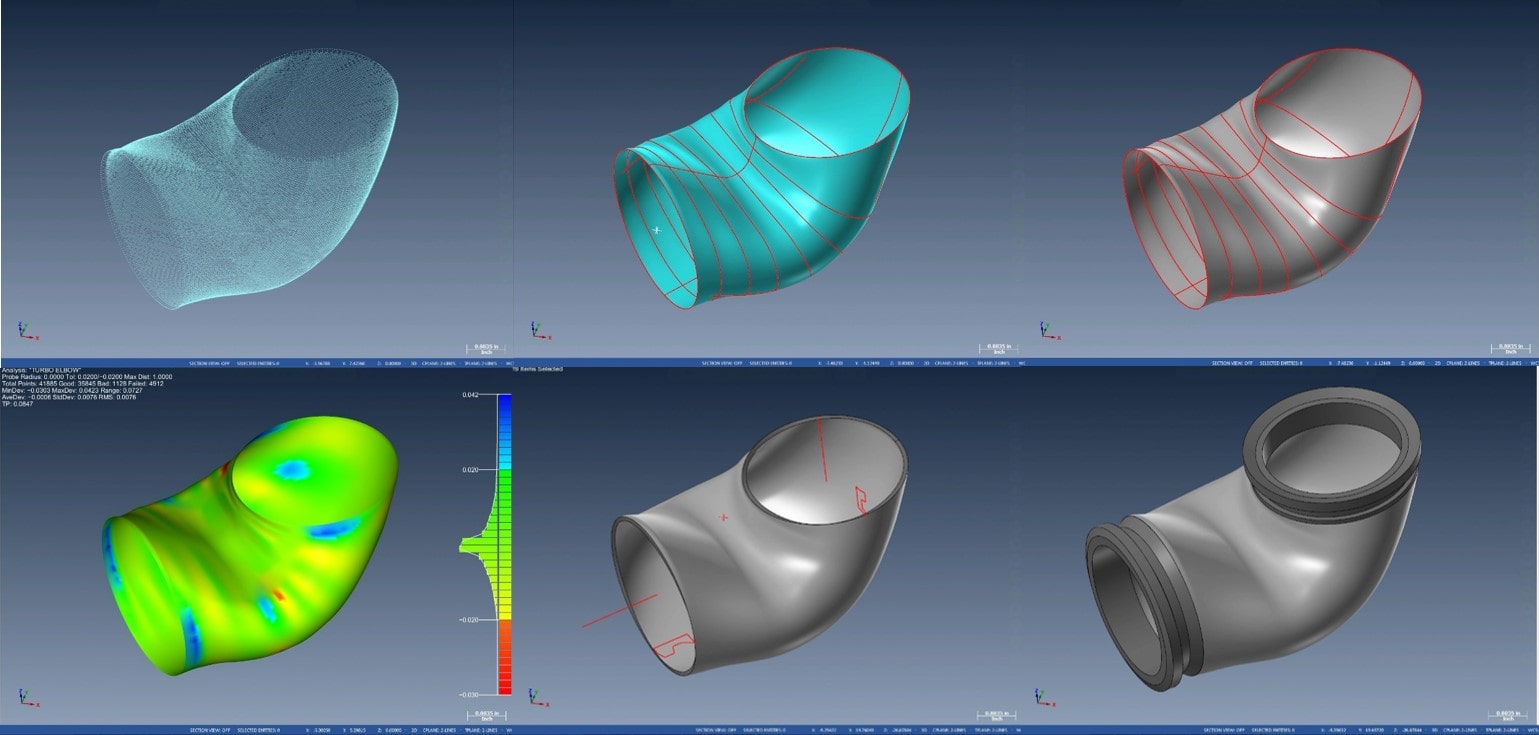

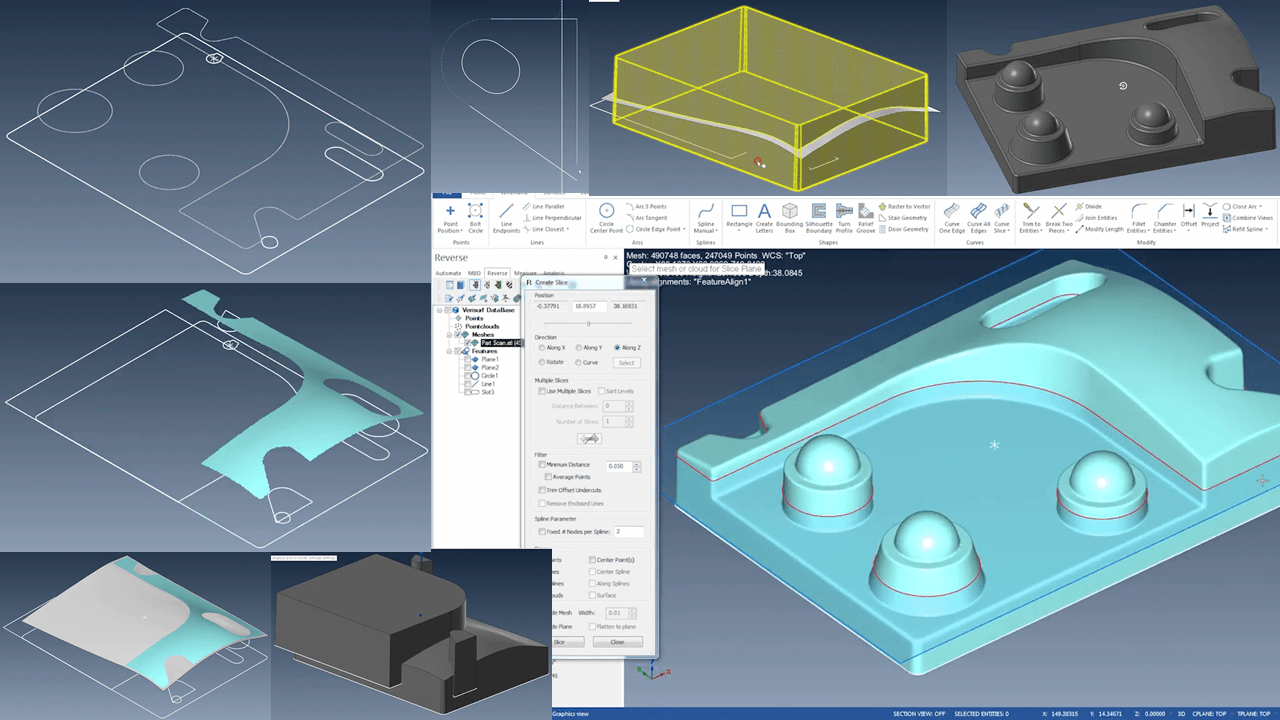

2. Import scanned dataset into Verisurf SCAN DATA SUITE and reverse engineer the as-built surface

- Point and mesh conversion to NURBS surfaces and wireframe/curve entities with tools to live-tweak (e.g., push-pull) entities

- Transform captured and constructed data with live, intuitive CAD and working coordinate system (WCS) tools

- Advanced solids creation and editing from scanned points, constructed features, and meshes

- Solids extrude, fillet, chamfer, re-size, boolean edits, normalize, and capture design intent or as-built

NOTE: Reverse engineering the as-built model often involves scanning and modeling only part of the full workpiece. It may be just one particular feature or surface that is of interest for manufacturing, and not the complete part or assembly.

Read how AIT uses Verisurf for big time and money savings reverse engineering the as-built model before CNC machining.

SIMSCAN Basic Specifications

SIMSCAN performs high-quality 3D scanning regardless of any restrictions from the working environment. It is ideal for 3D scanning both narrow spaces and large-scale parts. Users can accurately capture every detail of objects and construct 3D models in a very short amount of time with the help of this metrology-grade 3D measurement instrument.

- Single-handed control – SIMSCAN’s full metal housing provides solid protection and ensures extraordinary durability. Weighing only 570 g and dimensions of 203 × 80 × 44 mm, SIMSCAN portable 3D scanner brings unparalleled simplicity for scanning anything with one hand.

- Remarkable portability – SIMSCAN boasts a compact size and excellent portability. No matter if in narrow spaces or under huge objects, SIMSCAN portable 3D scanner can conduct 3D measurements anywhere and anytime. When paired with wireless communication link AirGo Pro, it supports mobile and flexible 3D scanning and data viewing.

- Narrow-space measuring booster – Compared with its competitors, SIMSCAN has a much shorter camera distance of 130 mm, which forms a steeper view angle to 3D scan narrow spaces. Therefore, SIMSCAN is more capable of capturing accurate and complete data in hard-to-reach areas like deep grooves and ensures users capture full-field data.

- Detail, everywhere – With its built-in HD cameras and three scanning modes, it realizes high-precision scanning with an accuracy up to 0.020 mm. It can accurately capture the 3D data of objects with complex surfaces or in confined areas.

- Smooth 3D experience – SIMSCAN can 3D scan objects with a rate up to 2.80 million measurement/s thanks to its sophisticated algorithm. It is designed to offer users a smooth and efficient 3D digitizing experience.

Verisurf SCAN DATA SUITE

The Verisurf SCAN DATA SUITE is the ideal optimizer for handheld 3D scanners and similar technologies. Users benefit from a complete toolbox for both reverse engineering and profile inspection, especially suited to complex contours. Full-powered CAD in a comprehensive but easy to learn interface, and workflows streamlined for today’s operators, provide the user experience that technical professionals want.

- Fast import of large point clouds, meshes, and CAD models in any industry-standard format.

- Precise rendering of scan data quickly identifies voids and outliers for easy cleanup and decimation.

- Scan data alignment and mesh editing tools achieve watertight mesh models ready for STL-based additive manufacturing.

- Automated feature extraction and NURBS surfacing produces precise, machinable surfaces in minutes.

- Finish the job with a complete 3D CAD system including wireframe, surface and Parasolid™ solid modeling, detailed drafting, and intelligent MBD for manufacturing.

- Fit clouds or meshes to CAD surfaces and create revealing color maps for profile analysis and quality reporting.

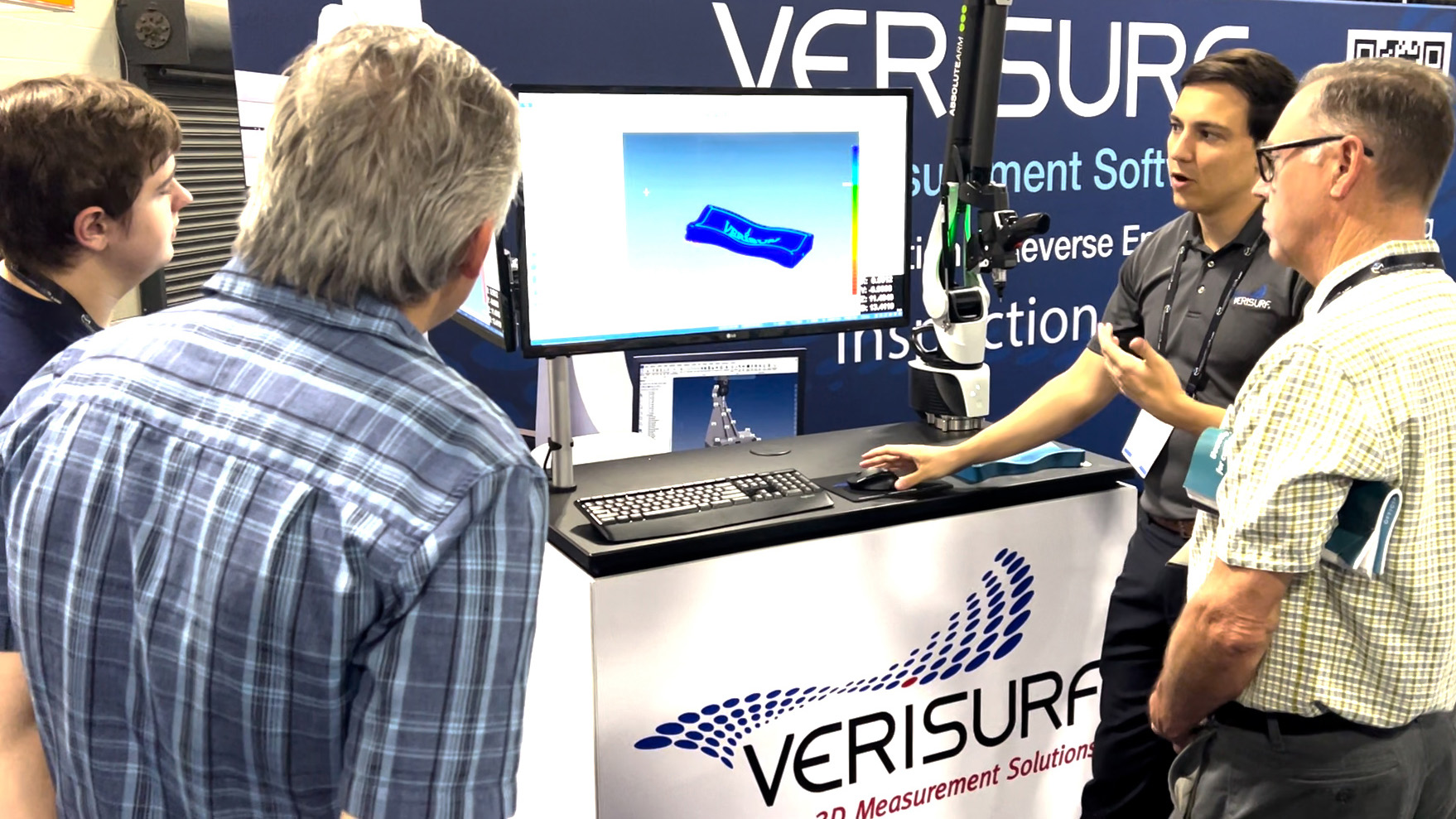

Verisurf Training & Support Services

Verisurf live training classes are taught by experienced dimensional metrologists skilled in the application of CMMs, portable CMM arms and laser trackers, scanners, and Verisurf to a wide variety of 3D measurement applications including: inspection automation, tool building, 3D scanning and reverse engineering.

Verisurf instructor-lead training classes are customized to each customer’s applications, parts, processes and people and are held either at the Verisurf corporate training center or at a customer facility.