Coordinate Metrology Certificate Program

Approved by State of California

Nick Real

Cerritos College

Teaching parts are machined and inspected on the shop floor following today’s trend towards in-process inspection.

The Design Engineering Lab at Cerritos College utilizes a popular 3D CAD software and the latest in additive and subtractive prototyping equipment.

Second-year student Steve Dorado is studying to earn his Associates degree and become a Certified CNC Programmer. In addition to his studies he holds a job in the industry as a machine operator.

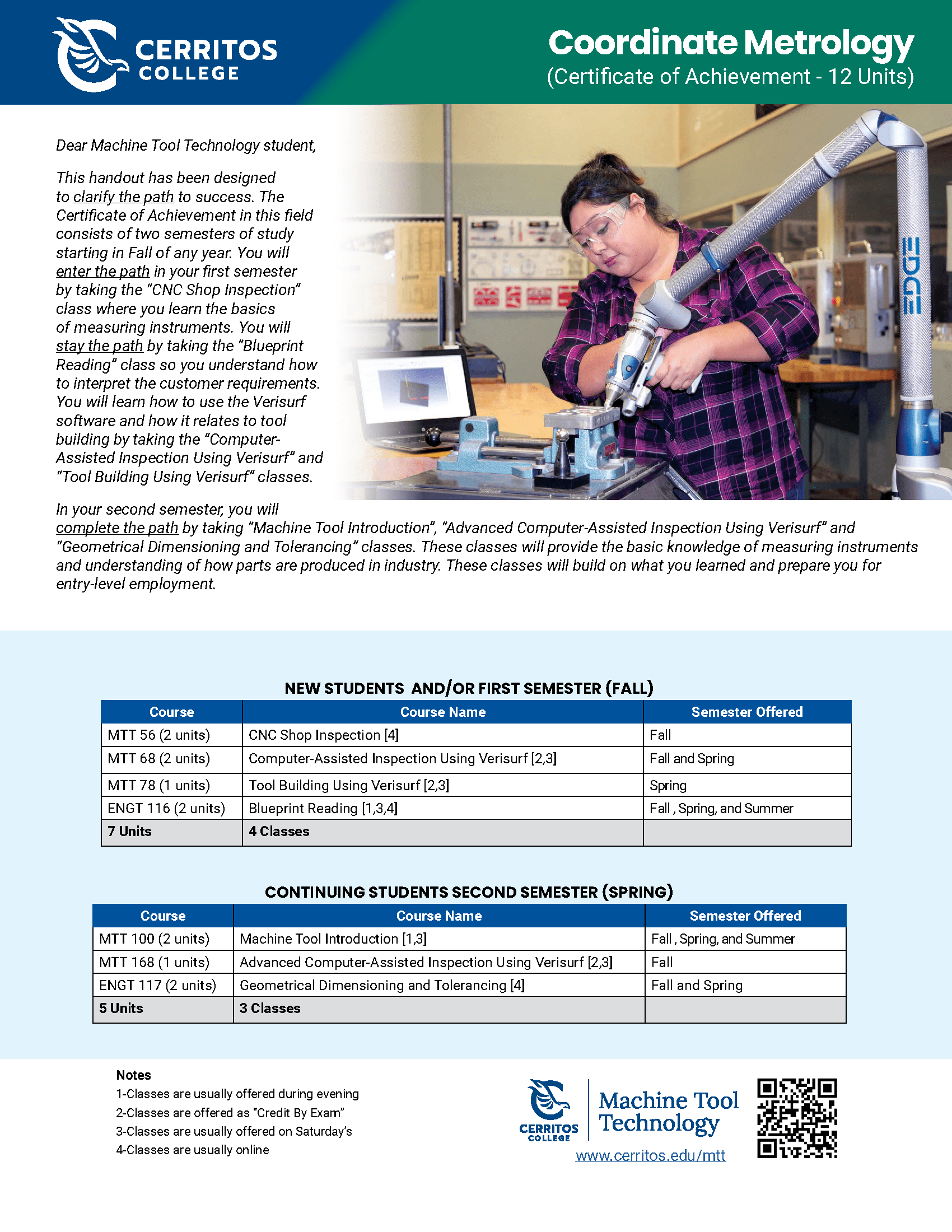

Students learn how to use Verisurf software and how it relates to tool-building by taking the “Computer-Assisted Inspection Using Verisurf” and “Tool Building Using Verisurf” classes.

Cerritos College, Cerritos, CA, has been recognized as the first community college in California to offer a “Coordinate Metrology” certificate of achievement approved by the Chancellor’s office.

The program was made possible through the collaborative efforts of the teaching staff and donations of product and curriculum support from Verisurf Software and its industry partners. The program is significant in that it closes the loop for students in the concept of model-based manufacturing, including design, reverse engineering, manufacturing, quality inspection and reporting.

The Coordinate Metrology program is a crowning achievement for Cerritos College as it relationally and digitally connects practical elements of the department’s applied technology curriculum. In industry this is commonly referred to as “maintaining the digital thread.”

To fully appreciate the significance of the Coordinate Metrology certificate program we must look back to 2000, when Yanick (Nick) Real, Instructional Dean—Technology Division at Cerritos College, joined the staff and laid out his vision for the applied technology program. Real identified early on that the industry was rapidly changing and designed coursework to reflect the times.

Technology was taking on a greater role as manufacturers began to migrate from 2D drafting and manual processes to 3D Model-Based enterprises with more automation. The education program was behind the industry curve and required revamping. The coursework lacked scalability. Students needed more options and flexibility to move into the workplace at various levels.

The realities of the industry were reflected in the job market, as well.

Teaching parts are machined and inspected on the shop floor following today’s trend towards in-process inspection.

“In the beginning, there were still manual manufacturing/machining jobs, but the decline had started. For people that could pick up extra skills, there was an opportunity to move into machining technician positions; for others, their jobs were eliminated or replaced by technology-driven manufacturing,” Real said. “The days of line workers are rapidly being replaced with technicians. The difference between a line worker and a technician is technicians have expanded skillsets, increased responsibility, and accountability—with this comes increased compensation.”

Trade skills used to be inherited: If your dad was a machinist, you were probably going to be a machinist. Today, things are different. Through applied technology and communications, more people are exposed to the wonders of manufacturing. They are able to develop a passion for it, even if it has not been a part of their family history. The applied technology programs at Cerritos College are giving more people than ever before access to the opportunities afforded trained technicians.

Right-Sizing Education

Cerritos College by design has placed its coursework offerings at the heart of manufacturing technology, with strong ties to supporting educational institutions, industry, and community advisory committees. The program gives students of all ages, starting as early as ninth grade (about 14 years old), the opportunity to gain an introduction to manufacturing technology. Based on interest level, aptitude and career choice, students can go as far as they want, from certificate programs to an Associate degree or Bachelor of Science degree.

The High School Connection

Cerritos College embraces a National program called Project Lead The Way (PLTW). In essence, the program allows high school students to take specified courses in applied technology while receiving college credit. Lynwood High School, Lynwood, CA, is one of the most active high schools in the program, under the direction of Engineering Instructor Christian Munguia. PLTW has been in place at Lynwood High School for seven years; the goal is to get to students earlier and introduce them to manufacturing. “The value of learning through doing gives students a practical point-of-view, which helps them to better assimilate concepts,” Munguia said.

“This is evident by increased math and science scores among students participating in the program.

The Design Engineering Lab at Cerritos College utilizes a popular 3D CAD software and the latest in additive and subtractive prototyping equipment.

“In addition to introducing students to manufacturing, the program teaches them how to work, how to live and how to contribute. Subsequently, they articulate better and are more likely to see a project through to the end.”

Industry Certifications available to high school students through PLTW include Verisurf Software, Solidworks Software, AutoDesk Inventor Software, and NIMS (National Institute of Metalworking Skills) Certification.

PLTW serves as a primer for students considering manufacturing as a career path. It also provides an introduction to college-level certificate programs and college credits toward degree programs.

Years ago, industrial arts programs at the high school level were nearly eliminated. Today, many of these programs are being reintroduced, with closer ties to real-world applications and industry relevance. For many, the path to becoming a manufacturing technician now begins in high school. With the right exposure, a student can gain a real interest in manufacturing and gain a greater appreciation for subjects like math and science. Applying these subjects through the practical applications of machining, robotics, 3D design, and engineering makes the light burn bright for many students: They are now purpose-driven. The concept of combining practical application along with theoretical teachings is powerful.

Associate’s Degree and Certificate Programs

Cerritos College offers classes with standardized curriculum on many aspects of manufacturing, including Machinist, Numerical Control Machine Operator, Numerical Control Tool Programmer, Coordinate Metrology, Tool, and Die Maker, CAD Designer, CAM Programmer, Plastics and Composites Technology, Fabricating and Woodworking. Many of the courses offer certificate programs, as well as credit toward an Associate degree.

Bachelor of Science

Cerritos College partners with Northwood University to offer students who want to continue their education and receive a B.S. in Applied Management with a technical emphasis in Machine Tool Technology. Northwood offers cost-effective, accelerated degree completion, and the eligibility criteria are in line with the Associate degree in Machine Tool Technology offered by Cerritos College.

“The whole idea behind the programs at Cerritos College is to enlighten students, as early as possible, about manufacturing technology as a vocation and viable career path,” Real said. “Once the passion has been ignited, we want to provide students the most comprehensive and practical education we can—learning by doing.”

Coordinate Metrology and the Digital Thread

Second-year student Steve Dorado is studying to earn his Associate’s degree and become a Certified CNC Programmer. In addition to his studies, he holds a job in the industry as a machine operator.

Today’s design, manufacturing, and quality engineers are becoming increasingly accountable to maintain a digital workflow, end-to-end. To this end, modern manufacturing is rapidly adopting model-based definition (MBD). When employing an MBD strategy, the CAD model becomes more than the nominal to which all parts are measured and inspected. MBD keeps the all-important digital thread intact—from design to manufacturing to inspection and quality reporting. Everything that defines the part exists in a single digital archive, including how to manufacture and inspect the part. Of course, comprehensive deployment of MBD in manufacturing can go far beyond this to complete Product Lifecycle Management (PLM), but it is important for students to understand the concept.

Reverse Engineering

Using coordinate metrology, reverse engineering is taught for use in determining best fit, producing legacy parts with missing CAD data, or manufacturing complex surface profiles—in each case adding value to the all-important digital thread. These are just a few examples of providing students with relevant and modern concepts that will increase their value as technicians in the workplace.

Quality Inspection

Quality inspection and reporting used to be a disparate process isolated in a quality lab. Today, it is much more integrated with the production floor through in-process inspection. Students are taught the importance of cross-platform compatibility, starting with the deployment of an enterprise inspection application and extending to all coordinate measuring machines (CMMs) and accessories. Today’s inspection software solutions are capable of serving the entire manufacturing enterprise. In order to maintain the digital thread, the software must be rooted in CAD and have the ability to import from, manipulate, annotate, model, inspect against, and export to virtually any CAD file format. At the end of the day, it is the job of inspection software to align and compare the nominal CAD model with measured points collected from the finished part, whether that includes a relatively small number of manually triggered contact points, or noncontact scanned point cloud data containing millions of points.

By Ray Elledge

Director of Education

Verisurf Software, Inc.

Verisurf Software, Inc.

Verisurf Software, Inc. is an advanced three-dimensional measurement solutions company committed to delivering advanced computer-aided inspection and reverse engineering solutions. Verisurf software helps manufacturers of all sizes and industries produce higher quality products in less time and at a lower cost with automated, Model-Based Inspection processes. For more information, visit the Verisurf website at https://verisurf.com.