Fabtech 2025

September 8-11, 2025

McCormick Place

Chicago, Illinois

Booth A1006

North America’s Largest Metal Forming, Fabricating, Welding and Finishing Event

FABTECH will bring together over 40,000 buyers and manufacturers to the McCormick Place, September 8-11, 2025, to explore 1,500+ world-class suppliers, discover innovative solutions, and find the tools to improve productivity and increase profits. There is no better opportunity to network, share knowledge and explore the latest technology. Gain insights into industry trends that will help you prepare for what’s ahead.

SEE DEMONSTRATION AND CONSULTING ON THESE TECHNOLOGIES FROM VERISURF AT FABTECH 2025

Large Volume Field and Industrial Machinery Measurement

Optimize your unique large-volume jobs with modern laser tracker technology and Verisurf software. Do things with one operator that many have to do with two.

Automate the whole process with extremely intuitive, graphical electronic work instructions (program plans) that are a must when you have to work far from the device and computer workstation.

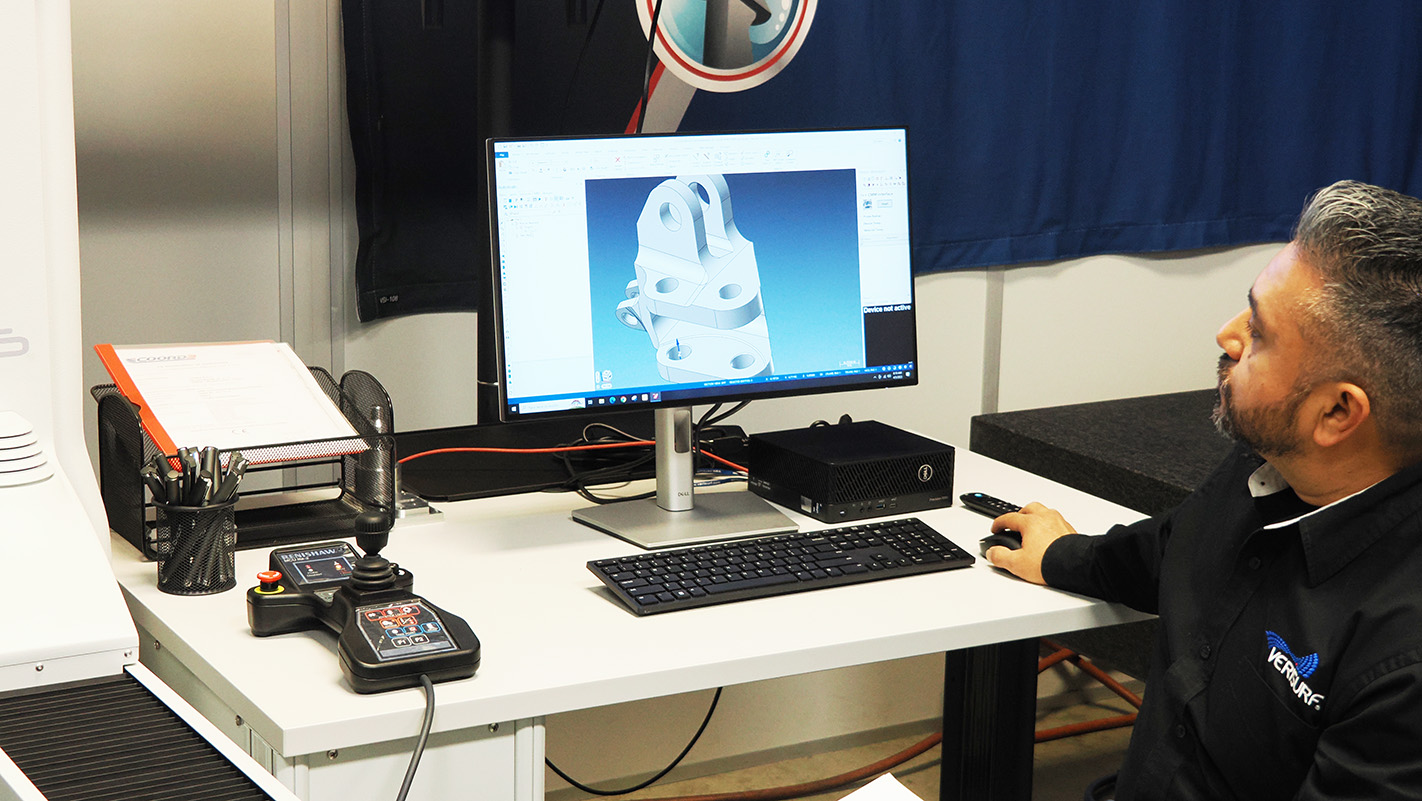

CMM Programming – Productive for All Skill Levels

CMM programming right inside a full CAD/CAM system. Use the same software for your CMM paths that is used for CNC milling machine paths. This is not a rudimentary add-on, it is a high-powered, full-functioning CMM software that programs and operates all brands and types of CMMs, including 5-axis systems. Verisurf replaces many legacy OEM software packages that were designed “old-school” requiring lots of training and expertise to learn complex coding and text editing.

Portable CMM First Article & In-Process Inspection

See how you can vastly improve your first article and in-process inspection jobs in less time and complexity.

The solution also requires considerably less training and experience from the system operators, while minimizing the pre-inspection preparation and setup time.

3D Scanning Inspection & Reverse Engineering

Verisurf optimizes both the scanning process and post-processing workflows for both reverse engineering and inspection. Inspection includes automated workflows, automatic feature extraction, full model-based GD&T, and support for all scanning devices. Reverse engineering includes mesh creation, cleanup, filtering, optimization, registration/alignment, and full CAD-supported parametric modeling.

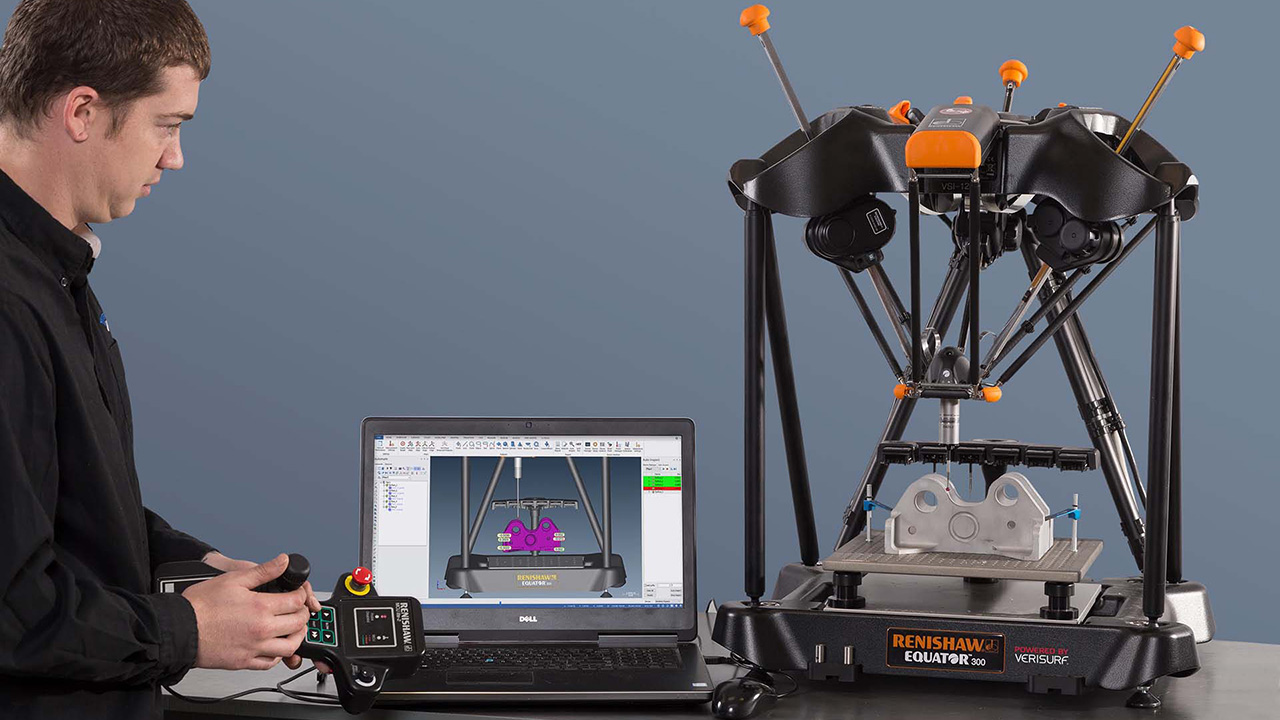

Shopfloor Automated Inspection

The Verisurf CMM Master is an optimized Renishaw® Equator™ automated gauging system upgraded with Verisurf software and volumetric error compensation mapping. This creates a shopfloor CMM that maintains the efficiency of comparator mode but eliminates the extensive mastering process that requires baseline runs on a separate CMM.

Increased Productivity, 5-Axis CMM Efficiency

Take advantage of the productivity improvements that 5-axis CMMs have to offer. Verisurf adds unique path patterns, programming, and editing features to help users realize a rapid return on their 5-axis investment. Five-axis provides reduced setup time, fewer requirements for special fixturing, and less probe qualification time. Verisurf special features for 5-axis adds even more opportunities for process efficiency and control.

In these days when many manufacturing enterprises are seeing great staffing challenges, our experts can get you up and running quickly and then will support you through the path to excellence.