Tool Building and Inspection with the FARO Vantage Tracker Powered by Verisurf Software

THE COMPLETE SOLUTION

Tool Building and Large Volume Inspection with FARO Vantage Laser Tracker Powered by Verisurf Tool Building and Inspection Software

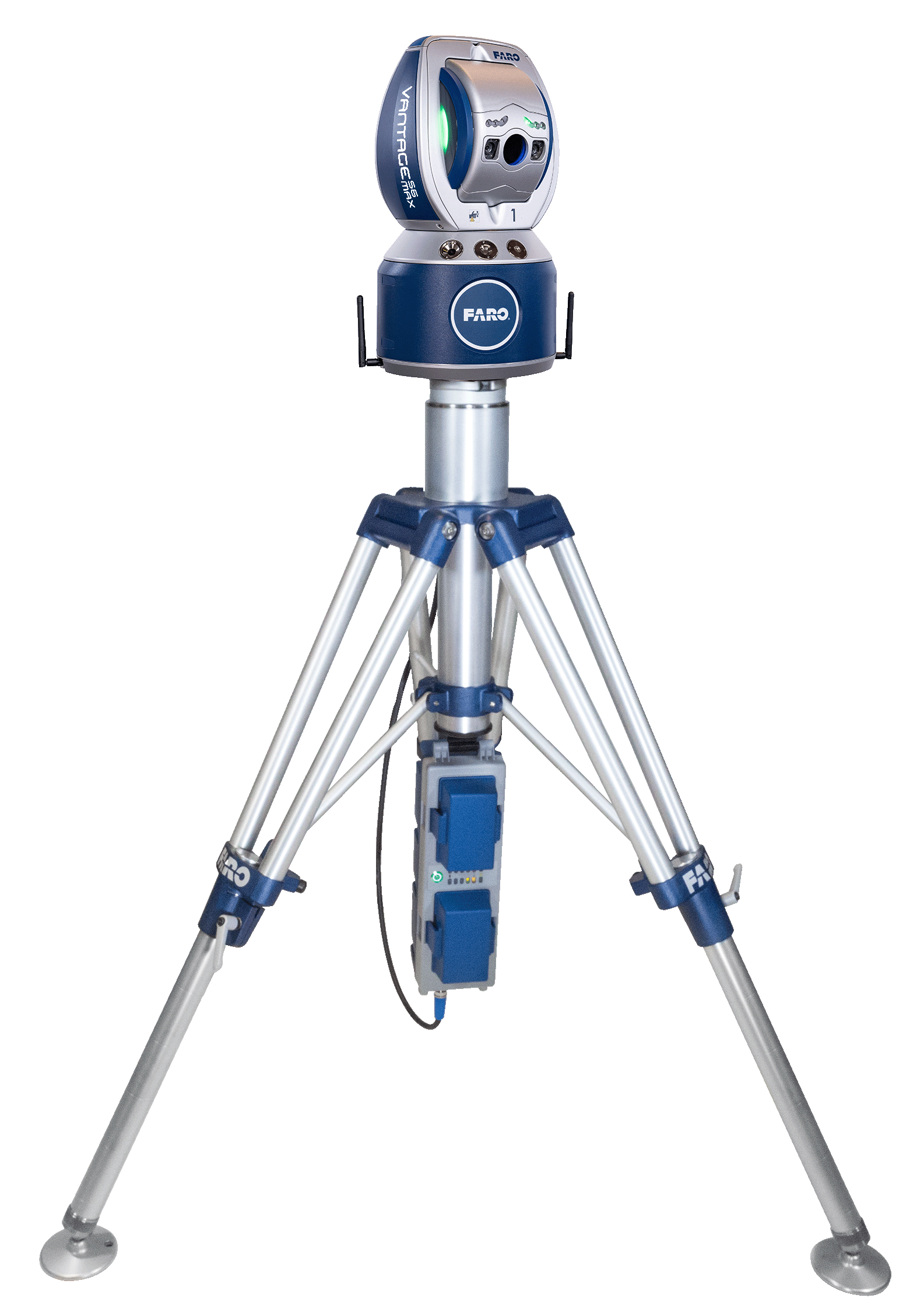

The FARO Vantage Laser Tracker, powered by the Verisurf Tool Building & Inspection Suite, is a complete metrology solution that provides efficient, computer-aided tool-building and measurement for medium-to-large scale inspection applications.

Verisurf’s laser tracker productivity starts with its easy-to-use CAD/CAM experience. It features intelligent MBD (model-based definition) that speeds measurement planning while optimizing tracker operation and workflow. Additional performance is provided by powerful device controls and highly repeatable inspection plans for unparalleled process control.

Whether you are inspecting, building tools, or reverse engineering, Verisurf gets the best performance from the Vantage Max! For aerospace tooling, automotive robotics and assembly line, energy, shipbuilding, or industrial machinery commissioning, Verisurf software and the Vantage Max provide the highest performance and accuracy available.

Realize higher productivity with a FARO Vantage laser tracker powered by Verisurf:

- Ideal for large volume, high precision alignments, guided assembly and repeatable inspections

- Solo operation optimized with powerful controls and mobile apps

- Verisurf Tool Building & Inspection Suite delivers rapid return on investment

- Custom training for fast implementation

- Unmatched, timely, customer driven enhancements and technical support

FARO Vantage Laser Tracker Basic Specifications

The FARO® VantageS6 Max and VantageE6 Max Laser Trackers offer comprehensive, large-volume 3D measurement up to 80 meters, significantly streamlining your organization’s processes and reducing inspection cycle times — all while ensuring complete confidence in the results.

- The VantageS is intended for short-to-long range measurement applications of up to 80 meters, while the VantageE supports short-to-medium range applications of up to 35 meters

- ActiveSeek™ FARO’s patent-pending feature to quickly and efficiently locate and lock onto a target allowing the Vantage to follow a moving target, even behind obstacles, and lock onto the target again when it is stable

- Integrated Absolute Distance Measurement System (iADM) – Vantage is the only tracker that uses one laser to measure angle and distance with iADM to ensure exceptional accuracy

And more:

- High accuracy with virtually no drift

- Easy transport and setup – no master control unit required

- Dual, hot-swappable battery

- Tested and proven, rugged design and construction

- IP52 compliant water and dust resistant

Popular High-Tech Option for the Vantage Laser Tracker

6Probe

Vantage Max laser trackers maximize 6 degrees of freedom (6DoF) measurement capabilities via the optional 6Probe, enabling precise measurement of hidden areas and small features. With kinematic self-identifying styli, you can change probing tips quickly and measure without any recalibration, plus measure hidden areas outside of the tracker’s line of sight with wide acceptance angles.

- Eliminate SMR nests

- Measure hidden areas outside of the tracker’s line of sight, while limiting device movements

- Change probing tips on the fly with kinematic self-identifying styli

- Enable CMM-style probing in small, tight and hard-to-reach spaces

- Quickly scan surfaces with high-density using a 1,000 Hz measurement rate of single beam iADM

Verisurf TOOL BUILDING & INSPECTION SUITE

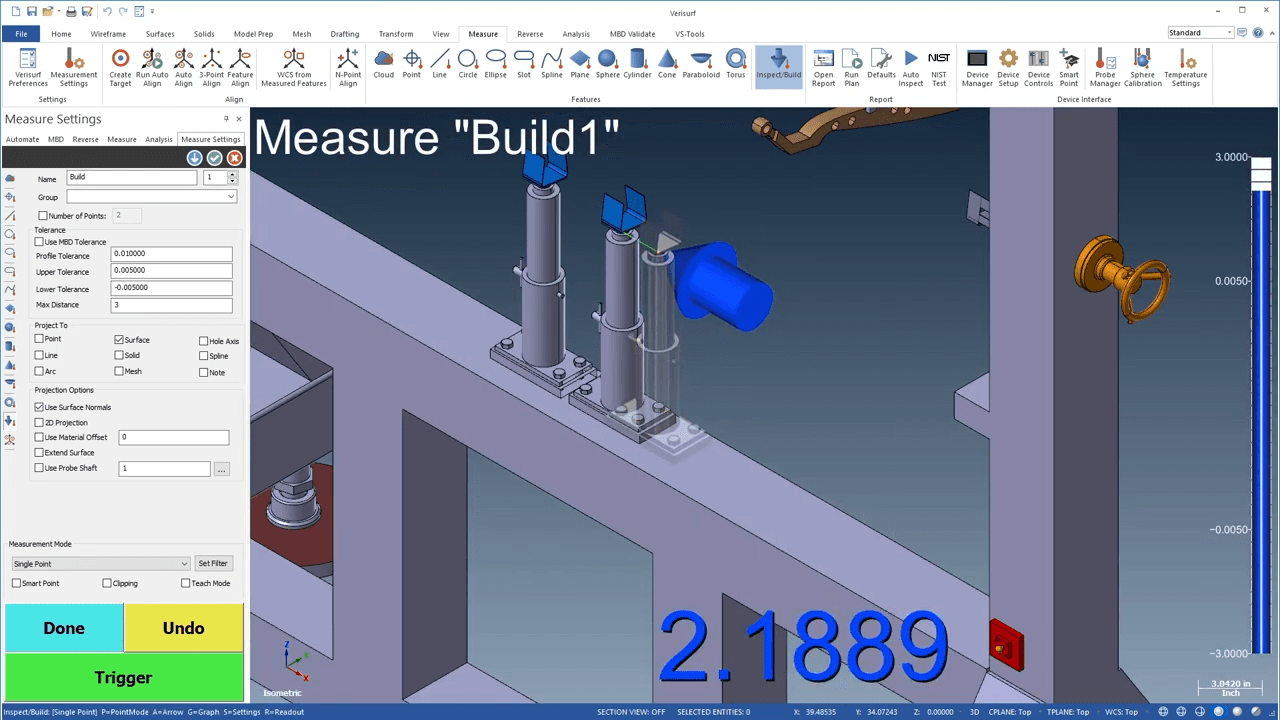

- Quickly and accurately set tooling details with real-time “build-to” computer aided assembly to CAD

- Adjust, shim, ream, and perfect the assembly followed by instant QC inspection report of the completed job

- The integration of CAD and metrology reliably connected to tool-building is a worldwide standard set by Verisurf

- Widely recognized as the standard of excellence for tool building at most major aerospace and automotive manufacturers

- Several live, color-coded graphical and sound feedback indicators keeping the operator informed and alerted to measurement and compliance conditions

- Easily report valuable detail with multi-color clarity of measurement results

- The fastest align-inspect-report workflow available

- Memorize steps to create reusable plans for repetitive jobs and process control

- Embrace model-based definition (MBD) with “interactive GD&T” imported from native CAD or self-applied, then automatically employed by the software for real-time application in measuring and reporting

- Direct, fast import of all major CAD file formats including massive files with ease

- Qualified, aerospace CAD file translation validation

- Fast and simplified drift monitoring and reporting

- CTE compensation, monitoring, and reporting with customizable temperature alarm

- Device station moves made fast and easy with Auto Align and intuitive bundling

Free mobile apps available to assist tool building tasks:

VS Companion

Take advantage of wireless mobility and touchscreen gestures to run inspection plans fast with the Verisurf Companion App

Click Here to Learn More

VS Watch

Enjoy greater mobile measurement agility with the convenience of hands-free DRO monitoring on Apple Watch or WatchOS devices

Click Here to Learn More

VS CTE

Quickly determine change in length for common manufacturing materials due to temperature effects with the VS CTE (coefficient of thermal expansion) app for Android

Click Here to Learn More

Verisurf Training & Support Services

Verisurf live training classes are taught by experienced dimensional metrologists skilled in the application of CMMs, portable CMM arms and laser trackers, scanners, and Verisurf to a wide variety of 3D measurement applications including: inspection automation, tool building, 3D scanning and reverse engineering.

Verisurf instructor-lead training classes are customized to each customer’s applications, parts, processes and people and are held either at the Verisurf corporate training center or at a customer facility.