Software Highlights – CMM Programming

SINGLE POINT ALIGNMENT

Verisurf Auto Align – Single Point Alignment – Precursor for Fully Automated Alignment

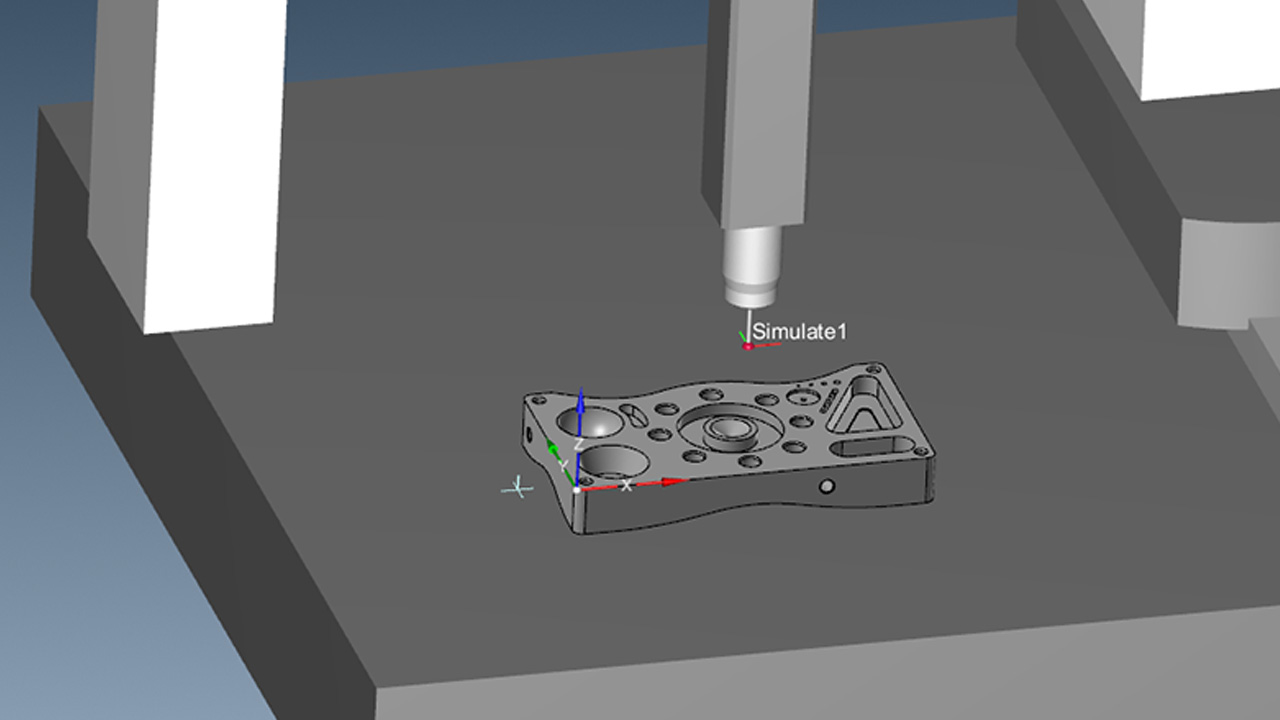

With Verisurf AUTOMATE Single Point Alignment, users can perform a one-point alignment in manual joystick mode to rough-align well enough to setup execution of the full, precision, automated alignment that begins the CMM program cycle in automated mode.

Measuring a single Auto Align point manually before commencing full automated Auto Align

Single Point Alignment Workflow

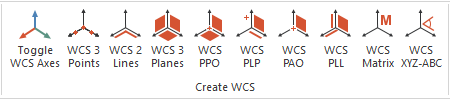

Secure the part on the CMM so that the part axes are in the same orientation as the CMM axes. Use Verisurf’s easy WCS tools to create the local part coordinate system that parallels the CMM’s.

Set part and its coordinate system orientation to parallel that of the CMM

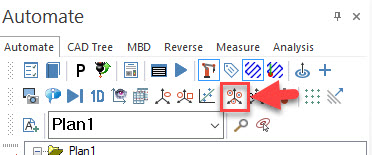

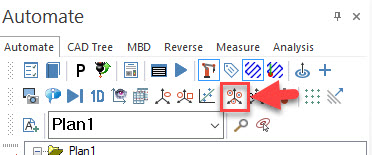

Create an Auto Align by clicking the Auto Align icon in the AUTOMATE toolbar

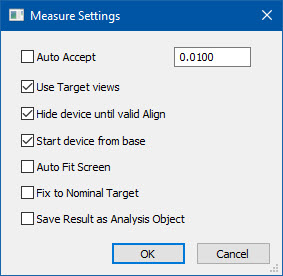

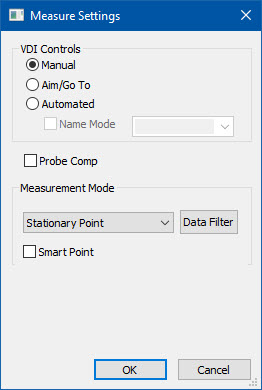

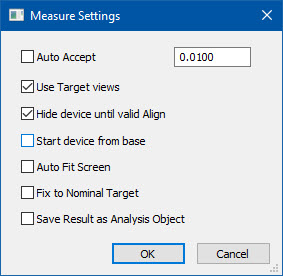

Double-click Auto Align Object in AUTOMATE Manager and in the Measure Settings check Start device from base

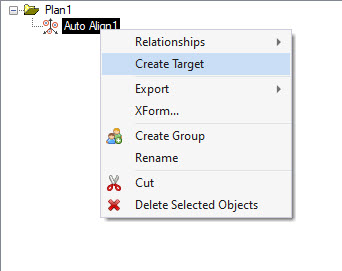

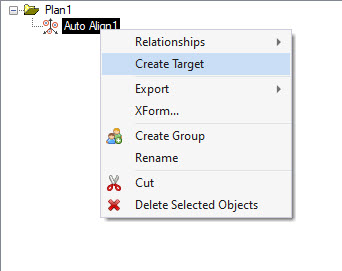

Right-click Auto Align object in the AUTOMATE Manger and select Create target.

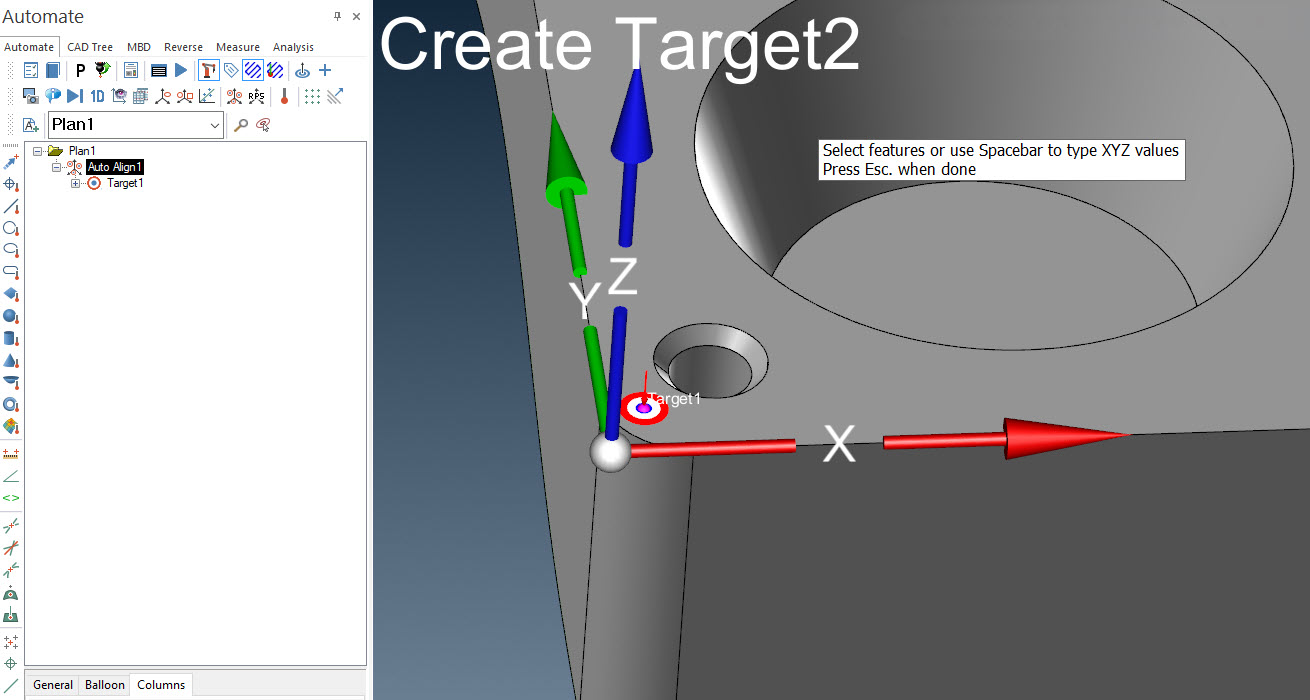

Click on the model to create the target near a feature that is easily recognized and will be readily accessed to measure your single locating point.

Pick a location that’s easy to find and measure the single point

Right-click the target in the AUTOMATE Manager and set to Measure Settings to Manual measure mode.

You are now ready to run the manual single-point alignment.

However, you can go ahead and setup the automated Auto Align to run the precision, full alignment after the single-point alignment:

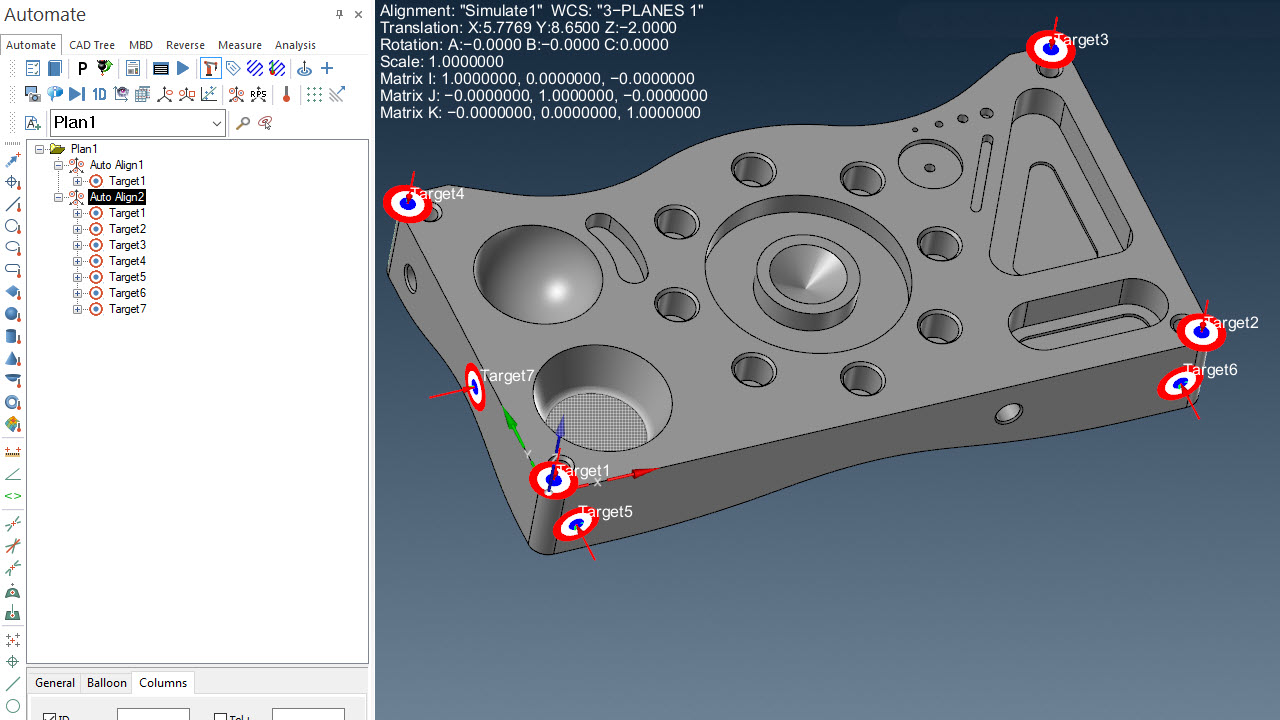

Create another Auto Align object in the tree.

Double-click the Auto Align object to open settings and this time uncheck Start device from base

Right-click the Auto Align object and select Create Target.

After single point alignment, you can create your 6+ target alignment points per your alignment strategy from your datum callouts, embracing all six degrees of freedom. Your CMM inspection plan is ready to run after the alignment successfully finishes within tolerance.

Six degrees of freedom, fully automated DCC Auto Alignment can be commenced after 1-point Auto Align

Automated Auto Align, Feature Align, or other alignment technique can follow your one-point Auto Align.