Verisurf X9 Supports STL Files

3D Scanning, Reverse Engineering, and Quality Inspection

Anaheim, California April 1, 2016

Verisurf Software, Inc. will be demonstrating its new release of Verisurf X9 during the Rapid Show in Orlando, Florida, May 16 – 19. The new release includes the addition of Verisurf SOLIDS, a complete 3D solid modeling application, enhanced scan data collection, processing and viewing, and the ability to inspect 3D printed parts using the STL model as the nominal. Other major productivity enhancements have been made to each of the modules that comprise the Verisurf solution – CAD, MEASURE, ANALYSIS, and REVERSE.

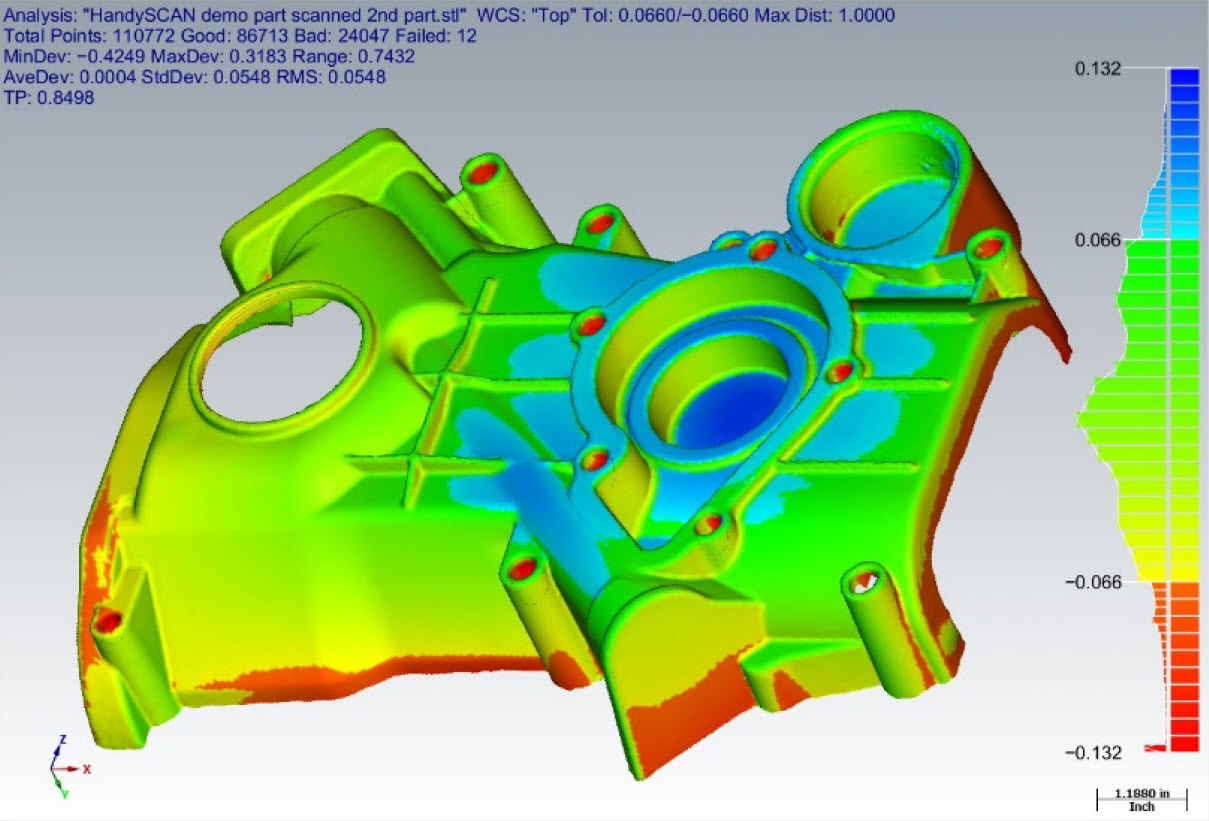

New Speed Menu options for point cloud and mesh objects greatly reduce the time necessary to scan, align and inspect part data. In the improved point cloud display with shading, the fine details of live scans look great and appear in real-time, as the data is collected. Analysis functionality has been optimized for increased speed and accuracy when using large scan data with the capability to process and display one million points per second in real-time. These enhanced capabilities have enabled new scanning and reverse engineering productivity features, including a ‘Do It’ icon to run the macro for quick alignment, registration, analysis, and reporting.

Verisurf software quickly converts point cloud data into a watertight mesh or STL models ready for surfacing and suitable for 3D printing. This includes alignment and merging of meshes, filtering, smoothing and filling holes. For some applications, like 3D copying, this step is as far as you need to go. Using Verisurf’s easy Align/Inspect/Report quality inspection process, 3D printed parts can be compared directly to the 3D STL model for accuracy. Verisurf Software can also be used to convert the mesh or STL model data into a true SOLID model. The intelligent model can be used in conjunction with other Verisurf modules, like Build for guided assembly, or Measure for automated inspection. Models can also be exported to virtually any CAD platform.

“At Verisurf our goal is to provide a comprehensive set of measurement tools so Quality and Manufacturing Engineers can effectively do their jobs. With the release of Verisurf X9 we continue to close the gaps in being able to maintain a digital thread between design, manufacturing, and quality inspection,” said Ernie Husted, President of Verisurf Software, Inc. “Verisurf users continue to provide practical insight necessary to help guide our software development.”

The new Verisurf Software functionality and added features are designed to make stationery coordinate measuring machines (CMMs), portable CMMs and 3D scanners more productive for automated inspection, guided assembly, and reverse engineering. Built on a powerful CAD platform, Verisurf Software provides a variety of manufacturing measurement solutions to meet the needs of the quality lab and in-process applications on the shop floor.

For more information regarding Verisurf X9 visit one of the following resources:

- Maintenance customers can download Verisurf X9 HERE

- New customers can contact Verisurf by email at sales@verisuf.com or visit https://verisurf.com

Watch the video here:

About Verisurf

Verisurf Software, Inc. is a measurement solutions company, committed to delivering advanced surface analysis, quality inspection, assembly guidance, and reverse engineering. Verisurf products and processes are vital to maintaining a digital thread between design, engineering, manufacturing, and finished part validation. Based on a powerful CAD platform, Verisurf is committed to digital Model-Based Definition (DPD) (MBD), open standards, and interoperability with all coordinate measuring machines and CAD software. Verisurf solutions help manufacturers produce higher quality products in less time. You can learn more about Verisurf at https://verisurf.com.